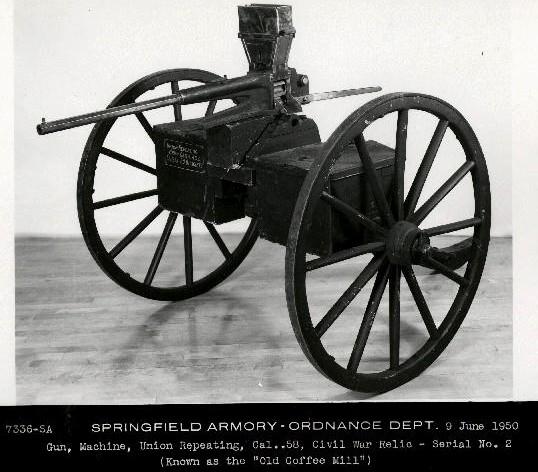

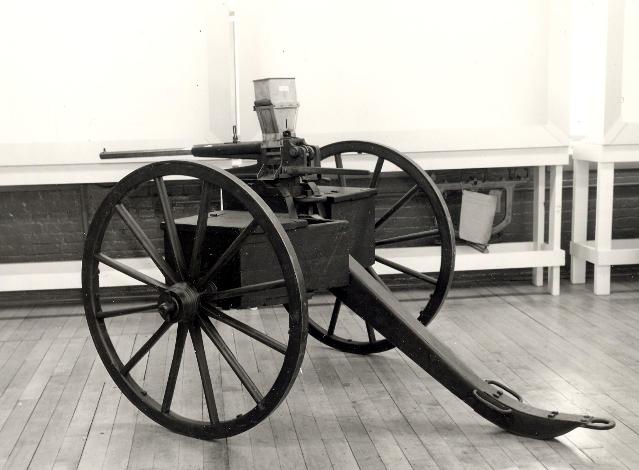

The Gatling is commonly seen as the first manual machine gun used by the US military, but it was preceded by several other designs, including the Union Repeating Gun. Also known as the Ager Gun or the Coffee Mill Gun, it was a single-barrel crank operated weapon developed prior to the adoption of self-contained cartridges.

Without reliable and suitably powerful (the early rimfire cartridges were fairly anemic compared to contemporary muzzleloading charges) self-contained cartridges, the task of developing a reliable and effective repeating weapon was quite difficult. The method used by the Union gun was to use steel cylinders to act as both cartridge and chamber – not unlike the English Treeby repeating rifle of roughly the same time. Each cylinder would be loaded with powder, wad, and projectile (or a premade paper cartridge) and have a percussion cap affixed to its back face, much like a modern primer. These loaded cylinders would then be loaded loose into the hopper atop the gun. Turning the gun’s crank would rotate a cylinder to pick up cylinders from the hopper, move them into firing position, move a locking wedge into place behind to more or less seal the breech, release a hammer to fire the round, drop the locking wedge out of engagement, and drop the now-empty cylinder out the left side of the gun. Those cylinders would be collected and reloaded – this system was also closely copied by the very first Gatling guns, before brass-cased cartridges became available.

The Union Repeating Gun had the luck of being one of the first guns of its type proposed to President Lincoln and the Union Army. Lincoln was something of a gun nut himself, quite interested in new technology. He took a personal interest in the gun after seeing it demonstrated in New York in the summer of 1861, and personally ordered 10 of them over the objection of the Ordnance Department. A further order of 50 more guns was made by General McClellan. The guns performance was mixed, and they saw use only in a handful of engagements. Certainly, they were not the decisive weapon Lincoln had probably envisioned, and that letdown would temper his enthusiasm for new weapons throughout the remainder of the Civil War. In addition, General Ripley (head of Ordnance) was adamantly opposed to the adoption of any new technology on the grounds that new designs were unproven and could not be relied upon, and resources were better spent mass-producing the tried-and-true percussion muskets that the Army was accustomed to.

The Union Repeating Gun was a reasonably reliable piece, considering the limits imposed by its ammunition. It had an effective rate of fire of 120 rounds/minute, although it was quite susceptible to overheating because of its single-barrel design. Interchangeable barrels were introduced to alleviate this issue, and a forced-air cooling system (using a fan linked to the firing crank) was designed but never produced. Consider that the standard load for the weapons was a .58 caliber Minie ball propelled by a 750 grain charge of black powder – that is a lot of heat building up in a single barrel. In fact, one test was observed by Colonel G.V. Fosbery (of Webley-Fosbery repute), who reported that:

…when firing at the rate of 100 discharges a minute, the flame of 7,500 grains of exploded powder and nearly 7 pounds of lead would pass through a single barrel in that time. The effect during the trial proved that the barrel first grew red and nearly white hot, and large drops of fused metal poured from the muzzle, and the firing had to be discontinued from fear of worse consequences.

(source: Chinn)

Getting a repeating gun reliable enough to get that hot was no trivial feat in the 1850s or 60s. However, the steel chamber cylinders never provided a perfect seal, and leaking gas could pepper the operators with small hot debris, as well as reducing the ballistic efficiency of the ammunition. The gun had an overall length of 56 inches and a 35 inch barrel, being mounted on a two-wheel carriage like a small artillery piece (which is how the military treated these sorts of guns at the time). Its maximum effective range was 800-1000 yards, although its lack of accuracy made it effective only against formations at that range. In formal testing, one sample was fired at a board fence measuring 60 yards long and 7 feet tall, and made 40% hits at 400 yards.

Union Repeating Guns were present at the battles of Harper’s Ferry, Middleburg, Yorktown, Warwick, and probably others – a captured one was used to fire on a Union observation balloon near Reams’ Station VA in 1864; possibly the first antiaircraft use of a machine gun (source: Pritchard).

The name “Ager Gun” comes from a sales agent for the gun in England named Wilson Ager, who filed a patent for it in England. The “Coffee Mill Gun” moniker comes from the appearance of the gun and its feed hopper. The actual designer is a bit uncertain, but is probably either William Palmer or Edward Nugent (or both of them working together). The guns were manufactured by the American Arms Company, which had been formed specifically for this gun. After the end of Civil War hostilities, the guns were sold off as surplus, less a few kept in arms collections.

Photos

A modern reproduction of the Union Repeating Gun sold at auction for $16,000 in 2013. Here are some photos of it, from Amoskeag:

Good article, Ian. Do you know if any of these saw shipboard use?

By the way, using separate, dedicated metal cylinders holding loose charge was employed in several contemporary small arms designs.

I really enjoyed this article. Generally there is not much written about the early manually operated machine guns.

Really interesting design, 19th century machine gun design is fascinating, it always seems like just as a I’ve got a rough idea of the designs available, a new one pops up with a new way of approaching the issue of rapid fire.

On that note, I can’t remember where if read about it, but there was apparently a proposed single barreled Nordenfelt that was intended to serve as a ‘LMG’ for cavalry- does anyone know anything more about that design?

Seventy-five grains (about 4.85g) of black powder generates much less heat than the corresponding quantity of nitrocellulose based smokeless powder. About 75% of black powder is inert, while only about 5% of modern smokeless powder is inert. One gram of black powder generates about 7.5 joules of heat while one gram of smokeless powder generates more than 4,000 joules – depending upon exact composition.

Brass cartridge cases remove a remarkable amount of combustion heat from an automatic weapon, generally more than 50% of the heat generated during firing. This is due to the high themal conductivity of brass which is roughly three time that of steel. Steel cartridge cases remove very little heat due to the low themal conductivity limiting the amount of heat they can absorb quickly.

This effect was probably a major reason for premature overheating of loaded steel chamber guns. The black powder didn’t generate much heat, but the steel chambers removed very little of that heat.

Thanks for that very interesting explanation, John.

Makes sense – I didn’t think about the heat removal from brass. Thanks!

In the history of arms manufacture, mills and lathes and clever action designs get the credit. But it seems as though brass rolling mills and stamping presses with deep draw-dies were the real break through to make the shells to enable other advances.

Interestingly enough though, machined (not stamped) brass shells have been around a long time and are still used today by a few people. Expensive, and of less capacity, but should have been possible to make in that era. Maybe they didn’t realize the advantages in heat removal and sealing, and maybe resizing brass in the field was not practical, or cleaning up residue would be an issue. Single use machined shells would have been cost prohibitive.

As a side note, Lincoln once filed a patent for a gizmo for river boats. Wasn’t practical, but he was obviously interested in mechanical things.

These erly mashinguns, are interesting, only one type predats it.it was the Danish musselloaded Espngol, invented by Shumacher and Loebnitz

in 1833, the later resposibel for the cartridges for it.

It was loaded with powdder bullit, powder, bullit, all the way to the mussle, the bullitshad a short fuse thru it. It was ignited, from the fron, then the soldier had to hold on tight ontil the last shoot.Some were reloded with loaded barrel inserts. These weapons, were used in the danish prussian war in 1864, with some susses.

That’s fascinating! …Has it occurred to you that is very similar to the modern “Metal Storm” automatic weapon concept? http://www.tonyrogers.com/weapons/metalstorm.htm

Excellent link, Jameszb — thanks! It will be interesting to see, as time passes and more information becomes available, how the designers and their backers ( such as DARPA ) propose to deal with the issues of overheating and everything this implies, as well as gas sealing and utilization between successive rounds in succession in the same entrained barrel.

I think heat transfer could be reduced and obturation could be improved if the chambers were given a brass or copper liner with a throat-piece that would extend beyond the mouth of the chamber about 4 millimeters or so and also of the same diameter as the chamber itself. On locking of the chamber, the copper (or brass) would be compressed slightly, achieving superior obturation and reducing the heating effect. This would mean more work for reloading the chambers, but I think the benefits would be worth it.

Another method would be to increase the wall thickness of the chamber to allow a groove to be machined into the front edge. It this groove, a precast ring of lead would be placed during loading to perform the same function outlined above. I wish I had at least a mill. There is so much I want to build.

The problems which were encountered again and solved in the way you suggest after WWii in the British ADEN aircraft cannon

The British development of the war time Mauser revolving chamber cannon

Wasn’t the same general principle applied to the DEFA 551/552/553/554 30mm aircraft cannon, and also possibly the Mauser BK27 ( 27mm ) and U.S. M39 ( 20mm ) guns?

All were derived from the Mauser. I think each team developed a diferent solution to the problem of gas sealing at the gap between the revolver cylinder and the forcing come of the barrel. 30mm cannon rounds are somewhat hotter than the ill fated .357 Maximum, which proved too hot for the magnum revolvers that were chambered for it in the late 80s.

From what I’ve read, the Aden used a loose brass/ bronze sleeve in the front of each of the cylinder chambers which was blown forward by chamber gas pressure on firing, to seal the gap.

a couple of interesting asides on the problems of high pressure rounds in revolvers (and guns with separate chambers like the coffee mill!) at least one author, (I’ll give the ref later – I need to do a few things before I get the chance to look it up) clained that a longer cylinder would have allowed the gap to be crossed after peak pressure when (PV=NRT – the ideal gas equation – pressure and temperature are related) the temperatures were lower too, and gas cutting wouldn’t occur – or at least would be less of a problem.

The ADEN and possibly some (?all) of the other revolving chamber cannon used gain twist rifling in their fixed barrel, so that the projectile’s driving bands were not stripped by the shock of going straight to the full spin rate, with gain twist, the rifling could start at zero or almost zero spin and build up to the full spin rate.

Thanks so much for the reply, Keith — very informative and interesting, as always. If I’m not mistaken, I think you actually meant to say that all the examples of revolver-type cannon I had mentioned derived their immediate ancestry from the Mauser MG213C / MK213 developed late in World War Two ( to avoid confusion with the much more recent Mauser BK27 — which is a direct descendant, and the primary gun armament of the Panavia Tornado MRCA ).

I just remembered. A fellow named Lyle Hegsted built his own Union Repeating Gun replica: http://www.floridareenactorsonline.com/Weapons.htm (Click on THE UNION REPEATING GUN for the history and construction to see the gun he made).

Big Al, thanks for a very interesting link. I also took the opportunity to read the various other articles associated with the same web site. Lyle Hegsted is certainly a highly capable and meticulous builder.

So many historical guns, and so little time ( sigh )….

Coincidentally, I’ve just read about this in C J Chivers book, The Gun. He gives an interesting account of the trials and adoptions of various early machine guns.

I remember reading that when I first went through my copy of “The Gun” — Chivers certainly did his homework when he wrote the book.

Thanks for writing and presenting such an excellent and informative article, Ian. I really enjoyed reading it!