You may recall that a week or two back I posted a video on some German trench armor at RIA. Reading up on that set of armor led me to International Military Antiques, who sells reproduction sets of the armor. I contacted them about getting a set to try some ballistic testing with Karl, and they generously sent one over. Thanks, guys!

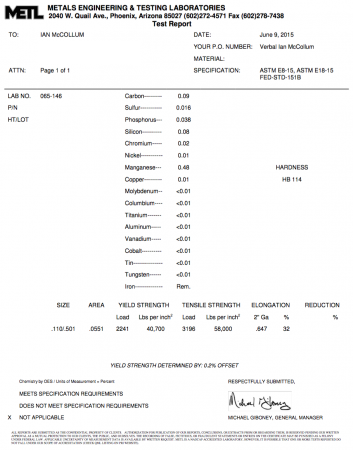

The first thing we did was to send the bottom-most plate to an metallurgical lab in Phoenix to be analyzed. We know the properties of the original German armor thanks to a report published by the New York Metropolitan Museum of Art in 1920, and testing modern reproduction armor would be a bit pointless without knowing how it would actually compare to the original material. Our report from the lab suggested that the reproduction armor was mild low-carbon steel, with a Brinell hardness of 114. Here is the complete report:

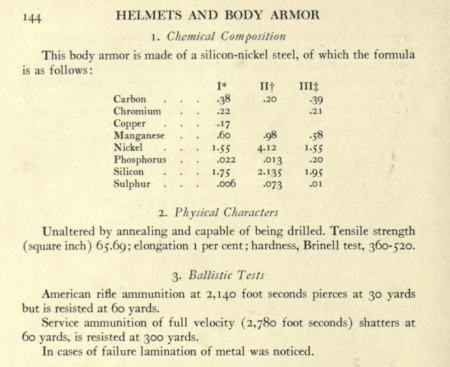

In contrast, the original armor appears to have had significantly more carbon content, and been surface hardened. It was a silicon-nickle steel, although those elements don’t really have anything to do with giving it hardness or other properties associated with armor – more likely that was simply what was available and would work. Here is the specific data from the Met’s 1920 book:

With this in mind, it became immediately apparent that our reproduction armor would not be up to the performance of the original. However, we felt it would still be interesting to test it with a variety of cartridges, including pistol ammunition at close range. Because of the hardness differential, we could definitely conclude that any shot successfully deflected by the reproduction armor would also have been deflected by the original. So, we proceeded to use a .32ACP (a Browning 1900) and a .45ACP (a GI 1911) at about 12 yards. We also tried a .45 Colt (a reproduction Richard-Mason conversion) with an plain lead bullet, because there were some instances of Old West gunfighters using scrap steel or iron as improvised body armor, which would have been soft like this reproduction armor.

After the pistols, we tried a .30-06 (from a Springfield 1903A4) at 300 yards, since we couldn’t quite duplicate the 400-yard shot used in the original testing referenced above. I also tried an 8mm Lebel (an M16 Berthier carbine) at 50 yards, just for kicks. And then the coup de grace, a round of Soviet WWII PZ explosive observation ammunition at 50 yards. You can see our full results on video:

It was more interesting than I thought it would be! I know IMA steel is nothing close to the original. From my experience removing rivets on German Maxims… I can tell you thats some hard hard steel! It does not like to bend! I would love to know what the Germans MG08 and 08/15 sideplates were made of. If you were ever interested in having it tested, I would donate some from demilled sideplates!

Australian outlaw Ned Kelly – who seems to have become Down Under’s version of Jesse James and Robin Hood combined) – was also noted for his use of homemade armor. Bryson’s “In A Sunburned Country” (one of the best travel books I’ve ever read) relates that Kelly’s legend and exploits have made the region where he met his satisfyingly gory end a popular tourist destination. A while back I read an alternative-history novel by an Australian Navy officer called “Kelly Country” in which the outlaw survived his brushes with the law and went on to become the president of Australia. Not much sillier than Turtledove’s stuff…

The gang only actually attempted armor once, and it led to 3 of them being killed and Kelly captured. At least one went down due to a round going between the plates of his armor and the other two died due to the simple expedient of the setting the building they were holed up in on fire and Kelly got taken down due to not having armor on his arms and legs.

But otherwise it did apparently work.

He is a pretty interesting character,there is a sense he was fighting against injustice. However his methods weren’t exactly lauditory, so he was misguided at best. Plain criminal at worst. As with most these things probably something in between.

This was an interesting test. While in the Marines we tested .300 Win. Mag. rounds reloaded with AP projectiles to see what effect they would have against light-to-medium armored vehicles, vehicle engine blacks and such at 300 to 500 yards. As a standard we used what was termed “12 inch inside diameter high-carbon steel casing (heavy pipe) with a 5/8” wall thickness. Our question was if this setup would penetrate the first encountered surface and be retained by the second to maximize ricochet damage. At 500 yards the first side was penetrated with an approximate ½” hole with very pronounced melt-flow on the back side … and then zipped right through the second side with a smaller hole but equally pronounced outflow of metal. We skipped the 300 yard tests and tried a piece of the same inside diameter casing but with a wall thickness of ¾”. The first shot penetrated the first wall looking much like a shaped charge penetration. The carbide insert from the AP projectile was caught and retained by the second side with approximately half the length of the insert protruding outside the second wall and “welded” in place. It was determined that the AP round “shed” the copper/brass outside layer while penetrating the first side and the carbide insert continued and penetrated the second side. The test was concluded with two shots. Next, a standard .30 cal AP round at 300 yards produced approximately the same results on the “lighter” sample with a 5/8 inch wall thickness. Aiming at the curved, just-off-center portion of the sample to simulate a curved surface such as armored vehicles used did not alter the results by much.

Well conducted and interesting experiment. It also sets to rest the questions of material composition and temper discussed in one of preceding articles. Good work gentlemen!

One episode of Mythbusters fired rifles at “armored cars”. The “armor” was thick phone books stuffed inside the door panels. The metal of the outide of the door panel caused the bullet to start to deform/tumble and the phone books could stop a deformed bullet. If the phone book was on the outide of the door it did nothing to stop the bullet.

I would like to see you guys try a phone book behind the armor.

So wierd to see both a french képi and a german armor worn by the same person ! It’s as puzzling as… hum… a katana-wielding US GI/marine, maybe ?

“PZ explosive observation ammunition at 50 yards”

I heard that legendary Finnish sniper Simo “White Dead” Häyhä was hitted with exploding rifle bullet, it hit his helmet and damaged his face. If it would be standard bullet he probably would be killed (steel helmets are not designed to be able to stop rifle ammo)

Silicon in iron and steel reduces corrosion. I believe nickel does as well. Reduced corrosion would certainly be desirable in trench warfare.

The “face hardening” of the original was most likely done by the Krupp process. Developed for face-hardening warship armor plate in the 1880s, it consisted of first forging and forming the plate (in this case, a cuirass) to shape, drawing and tempering it, then laying it face-up on a “bed” in an open-hearth furnace.

When the furnace heated it to “red heat” (just below the temperature at which the temper would start to fail), carbon monoxide gas (CO) was blown across the face. The heat would break the bonds of the carbon and O2 in the gas, causing the carbon to be deposited on and in the upper layers of the plate. The plate was then cooled slowly, often taking days for ship armor due to its mass and thickness (around 6 to 10 inches in that era); the cuirass would, of course, cool more quickly due to its lesser mass relative to surface radiating area.

In making warship armor, the treated plate would then be secured by brazing or sweating to a softer steel backing plate of equal or greater thickness. This acted as an anti- spalling layer to reduce penetration and help break up any shot and/or fragments that got through the front plate. Hence the term for this type of armor, “KC”, for “Krupp Cemented” plate.

The German WW1 cuirass was basically the “front half” of “KC” minus the anti-spalling layer.

As for that, plus bruising, etc., now you know why knights in armor, either plate or the earlier mail, wore a padded blouse called an “arming doublet” under it. It was not only needed for protection from projectile hits (longbow arrows, crossbow quarrels, bullets from “handgonnes”), but also for protection from avulsions caused by impact hits.

A mace could break bones and cause massive bruising even without breaking the armor. And the “knightly” broadsword was basically a four-foot steel crowbar that happened to have sharpened edges and a point. (The latter was rarely used, BTW.)

Finally, during the American Civil War, “sutlers” and others sold “armored vests” to the soldiery on both sides. Built much like this or a Renaissance plate cuirass, they were supposedly “bullet-proof”. In fact, most were cast iron or at best wrought iron (made the same way “potbellied” stoves were made), and were nowhere nearly thick enough to stop even a relatively low-velocity .58 Minie’ bullet from a rifle-musket. These could penetrate 1/2″ cast iron at 100 yards; a vest which could resist such a slug would have been at least 3/4″ to 1″ thick, and a front-only cuirass would have weighed over 70 pounds.

Not exactly practical.

By comparison, even without face-hardening, this cuirass stands a pretty good chance of being able to stop said “minny ball”. Although the lead splash would be spectacular, as with the .45 Colt lead bullet.

The man wearing it, however, would have a pretty good idea of what it was like to be hit by an NFL fullback. That 1,000+ foot-pounds of kinetic energy has to go somewhere…

cheers

eon

The guy in the cuirass would hardly have been “blown across a room” unless he flinched while getting hit.

In naval history, the guns always outdid the armor in a battle between ships of the same class, though penetration wasn’t always what did the ships in. In the Battle of Tsushima, the Japanese ships apparently targeted the bridges of their Russian opponents and fired shells filled with shimose powder. Said explosive had a nasty tendency to set even armor-grade steel on fire after impact.

Back to infantry-type plating and what-not, it has been observed that Kevlar is useless against a katana. Or am I wrong?

When your opponent decides to don “bullet-proof” armor, get the artillery or get personal with him (preferably with a nicely sharpened entrenchment tool or combat knife).

Weapon of choice questionnaire:

Given a choice of arms and armor sometime during a fictional depression era, what would you grab up to repel some upstart warlord gang? Be aware the brigands may have improvised armored cars or stolen tanks as well as regular plate body armor. You currently hold the high ground of the mountainous area through which the warlord clique must pass in order to continue wreaking havoc as the other roads have been secured by friendly forces. Sadly, you are in charge of a bunch of mostly inexperienced recruits and volunteers from a local village.

Arms

1. Steyr-Mannlicher 1888 long rifles

2. ZK-383 submachineguns

3. flamethrowers

4. entrenched minenwerfers or grenade launchers

5. 7.7 cm FK 16 nA.

6. 37 mm Maxim Pom-Pom auto-cannons

7. 25 mm Hotchkiss Anti-aircraft guns

Armor or terrain protection:

1. Armor? We don’t need no stinkin’ armor! ATTACK!

2. Steel helmet (your choice)

3. plate armor

4. trench network

5. wooden fortifications

6. Concrete fortifications

7. Screw the above and get the Vickers Light Tanks (the Mk VI C variants with 15mm Besa MG as the main gun)

Or, per the usual, screw the limited budget and add your favorite toys to the lists.

The questionnaire is a voluntary activity. You are not required to respond if you do not wish to do so. Please keep any and all criticism of this post humane and free of foul language.

Thank you,

Cherndog

“Armor or terrain protection:”

If you need to stop enemy tanks or AFV use Czech Hedgehog:

https://en.wikipedia.org/wiki/Czech_hedgehog

it should work considering “other roads have been secured by friendly forces” so it can’t skirt around

“Arms”

Considering “mountainous area” these should be light or designed so they can be dismounted to parts ease to transport (so-called mountain gun, see 2.5 Inch Screw Gun), also notice that you can exploit terrain to fire at enemy tank which couldn’t return fire due to restricted gun elevation. During early stages of Soviet Union – Mujahideen War 1979 – 1989 some Soviet Forces were ambushed in this manner, to solve this problem Soviet attach to their columns ZSU-23-4 Shilka AA defense vehicle able to fire at ambushers.

“In naval history, the guns always outdid the armor in a battle between ships of the same class.” That’s not true, think about Battle of Jutland, even with the greater number of capital ship(28 against 16 BBG, 9 against 5 Battle cruiser), the royal navy suffer heavier lost due to their design trade-off firepower for survivability, while German ship trade-off in contract aspect.

The one-sided result of Battle of Tsushima could contributed for many factors: Obsoleted Fire control system, Bad tactics formation. (Japanese fleet achieved “crossing the T” twice during the battle).

“Kevlar is useless against a katana.” It may thrust through the vest with enough force but definitely not slashed through it. I Crossbow and Sharpe blade are useless against stab resistance vest (not bullet resistance). https://www.youtube.com/watch?v=eKxrBJIaFpA

The different material is design for mitigating different threat. Body armor is not just build from solo Kevlar, it combine different components for dealing common threats. That’s why we have trauma plate and stab-resistance layers for the soft armor production.

According to the medical statistics, shrapnel & high explosive shock wave contribute most infantry casualty followed by the bullets. So I believe good piece of armor would still be a game changer on the battlefield.

Many people likes the exaggerating the effect of Japanese sword, the truth is it is just a cast-Harding technology applied for centuries by the both Smithers & Armorers. Interesting fact: check the Katana vs Tosei Gusoku (A common type of Japanese body amour during medieval age) https://www.youtube.com/watch?v=D9OvaL2W6BA

“Knightly broadsword” is a rather vague terminology, although there of course were no “official” terminologies back then. Still, usually broadsword refers to a Scottish Highlander sword of the 17th and 18th century. In any case, early “knightly” swords are nowadays usually called “arming swords”, which were still used with a shield in the weaker hand. Arming swords may have developed from the late Roman spatha, although there is no certainty of that due to lack of records and relative scarcity of archaeological evidence from the Early Middle ages.

The longer Late Medieval / Renaissance sword is usually dubbed “long sword”. The latter was a quite sophisticated “hand and a half” (most of the time) weapon with plenty of different fighting techniques, including many thrusting ones and different “schools” of combat, basically the whole package, which even Westerners these days (incorrectly) associate only with Samurai and other East Asian styles of swordplay. This included different styles and techniques of fighting against fully armored and non-armored opponents. These are known from preserved swordfighting manuals and “textbooks”, some of which were published (or re-published) after printing press became widely available and have thus been preserved for posterity (earlier only rich people could purchase such books). Rarely would a Late Medieval knight go to combat without his long sword and its versatility, although he might bring a mace in addition to it.

@eon – The hardening process you are describing is a form of “carburisation”. There were and are a number of different ways of doing it, the “gas” method being only one. The high variance in hardness of the original German trench armour may possibly be due to using one of the less well controlled methods that didn’t require as much specialised equipment.

As for “arming doublets”, they are known by many names, but “gambeson” is probably the most common. They were often worn on their own, and in many cases were considered quite adequate protection from most sword cuts or arrows. While in medieval Europe they were often worn underneath mail, we know that in prior times (e.g. the Romans and possibly the Viking era) and in areas outside of Europe mail was often worn with just regular clothes underneath and no gambeson.

As Euroweasel has noted, broadswords were generally from the late 16th and into the 18th century. They are a type of “basket-hilted sword”, with broadswords being double-edged, and backswords being single-edged. They are quite different from medieval swords in that they have a much more complex and protective hilt, the change being driven by the decline of use of armour and shields. Basket-hilted swords were the typical European military sword of that era, while rapiers and small swords were the corresponding civilian swords (although rapiers of course sometimes found their way onto the battlefield as well). Basket-hilted swords were used even into the Napoleonic era, ultimately being replaced by sabres. They are however still made today as dress swords for officers in British Highland Regiments.

Normal one-handed medieval swords are not heavy, were generally made of good quality steel, well balanced, and were quite sharp. They weren’t heavy “lumps” of metal by any means. And the points were in fact very useful, since the means of dealing with plate armour was to thrust in between the gaps in the armour.

Medieval plate armour was well made and often hardened and proof against being penetrated by normal swords and even arrows. Modern reproduction plate armour is not representative of medieval armour except in appearance, so take any Youtube videos you may see of how well it fared against various weapons with a grain of salt. Hmmm … I think this is where we came in …

As another poster noted, the Germans were carborizing the steel. That adds carbon to the skin of steel and makes the surface harder. It is a common industrial process today, used to work at a plant that did a lot of it. The plant fire brigade got to know that part of the plant well, it was a continuous process (had a conveyor going through it) and sometimes when the doors opened for another tray of parts the fire would get out and see if there was anything flammable near by. There were continuous annealing ovens there too, but it was the carborizing furnaces that were the fire hazard.

There are other ways of case hardening (which is what carborizing does). One is to hear up steel with an acetylene rich oxy-acetylene flame. Another is to heat the steel red hot then cover it in case hardening compound (Kasenit is a US brand), and some of the carbon will move into the skin of the steel, maybe one or two hundredths of an inch.

In the old days, or for gun shops looking for a pleasing finish, steel parts would be placed in secret concoctions of bone meal, ground up burnt leather, some really dangerous chemicals, etc., then heated up. Old single action army revolver frames were case-hardened that way. Basically a way to take mild steel and make the best of it.

Looking at what the Germans had used, it looks like they used what was available but case hardened it to make the best of it. Even if the steel had been heat-treatable, the parts could have warped badly. One good thing about case hardening is that a non-brittle core is maintained while the surface is made hard. That might work to one’s advantage with armor.

If Ian does another test, Kasenit is availablle for purchase in small quantities..

Nickel – Usually added to steel for toughness, corrosion. I dot believe some very hard steels also have nickel as a alloying component. Personal I think it was added to prevent cracking.

Does anybody of you have information concerning the hardness of

-WW1 tanks (or landships as they were called) armour

-WW2 tanks, separately for III Reich, Soviet Union and USA

-cold war tanks

For example there: http://tankarchives.blogspot.com/2014/02/pziii-armour.html you can read that Panzer III armour plate was 460…444 Brinell hardness. Also so far I know late WW2 German armour-plates were of lower quality due to lack of steel-enhancing elements.

BTW: Why inter-war / early-WW2 US tanks has so many machine-guns? I consider following tanks:

M2A4 Light tank:

2 x .30 machine gun fixed in sponsons (aimed by movement of whole tank), fired by driver

1 x .30 machine gun in hull, fired by co-driver

1 x .30 machine gun co-ax with 37mm gun

1 x .30 machine gun (AA) mounted to commander cupola

Together: 5 x .30 machine gun

M2 Medium tank:

2 x .30 machine gun fixed in hull (aimed by movement of whole tank), fired by driver

4 x .30 machine gun in hull, one in each corner

1 x .30 machine gun co-ax with 37mm gun

2 x .30 machine gun (AA) mounted to turret (optionally)

Together: 9 x .30 machine gun

M6 Heavy tank:

2 x .50 machine gun (linked together) in hull

1 x .30 machine gun in bow, fixed in azimuth, but can be elevated/depressed, fired by driver

1 x .30 machine gun (AA) mounted on turret hatch

Together: 4 x machine gun (2 x .50 and 2 x .30)

I don’t have a single reference handy for armor hardness of different countries and eras, although such a thing must exist somewhere… In general interwar and early WW2 armor was harder than later, and the Germans also used face-hardened armor with plates up to 35 mm thick. As armor got thicker, it was easier to manufacture somewhat softer armor. Very high hardness also became less important as penetrators (penetrating part of the AP projectile) increased in diameter from 8-47 mm to 57-128 mm and AP caps became more common.

In interwar tank design machine guns were thought to be very important, because the primary enemy and target of tanks was infantry. Some of the early US design went a little bit too far and typically the fixed machine guns were from later designs. The M2 Medium in particular was a product of the “land cruiser” type of thinking, which saw tanks operating independently from friendly infantry. The M2 did not have multiple turrets, but the same basic philosophy was behind the British A1E1 Independent, Cruiser Mk I and also the Soviet T-35 and T-28 tanks. In practice tanks could not expect to survive long alone amongst enemy infantry, no matter how many MGs they had, so the M2 Medium and the multi-turreted tanks were an evolutionary dead end.

The later M3 Light and Medium tanks had much less machine guns: M3 Stuart (light) and M3 Grant had 3, the M3 Lee had nominally 4, although one was often removed in practice.

““land cruiser” type of thinking”

It was also used in some 1930s/1940s bomber aircraft, it was belived that bomber with numerous machine guns can defend itself from enemy fighters. For example Kalinin K-7 in military variant would have 8 x 20mm autocannon and 8 x 7.62mm machine gun. During WW2 US Air Forces employed some YB-40 bombers, which were armed with 18 x .50 machine guns or more, but it was used only in 48 sorties.

The idea was that the YB-40s would carry no bombs, but the extremely heavy machine gun armament would defend the actual bombers against enemy fighters. It did not work very well, partially because the YB-40s had extra armor, carried a lot of ammo and had increased drag thanks to the additional guns. Those slowed the aircraft down so much that they could not keep up with the regular B-17s on the return trip. Their ability to defend the bombers was also rather questionable. Heavier than .50 cal guns were tried experimentally, including a 40 mm Bofors gun, although that one (obviously) did not get any further than initial tests.

Originally, WWI tanks came in two flavors: Male and Female. A Male tank had artillery as the primary armament. They were supposed to destroy enemy hard points like MG positions and bunkers, clearing the way for the infantry to breakthrough. To protect the male tanks from infantry assaults, the Female tanks were to escort them, armed with multiple machineguns. The tactics never quite worked out that way, but it does continue in some forms to this day, with the Female tank role being filled by APCs and Infantry Fighting Vehicles, primarily armed with lighter automatic or rapid firing armaments compared to the Main Battle Tanks. The interwar US designs were an attempt to combine both roles in one vehicle, which was mostly intended for infantry support roles. Tankers in Vietnam were noted for acquiring as many MGs as they could hide or weld on pintles for to allow defense from multiple vectors, thus reversing the trend in a specific set of circumstances.

Great video Ian and Karl. Any plans on getting some random plate the same thickness, 360-530 hardness and testing that?

The problem with body armor is that we tend to focus on penetration and overlook the effects of impact trauma on the victim. Even disabling the target temporarily can be effective in combat, and a solid hit can cause internal bleeding and organ damage, even if the projectile doesn’t penetrate the material. Still, a fascinating video.

I don’t know anything about WWI era armor plate. I do know that the M1911s produced during that time frame were not heat treated. They were extremely soft. I have seen this when working on original WWI era slides. (REM UMC, if it matters, but it really doesn’t).

AS I understand it, by the 1930s, the early pistols were showing some wear. The WWII era pistols had a hardened steel breeechface fitted to reduce wear.

The post WWII slides were heat treated. I think this started about 1947, (WWII slides were spot heat treated, and this was usually visible).

So, the .45 my mother carried when she was dating a soldier on leave in Paris, (before she met my father, after the war), was probably a M1911A1, though obviously I can’t prove it.

A century ago, they worked on making steel armor against battleship rounds. Gradually, by the 1950s, they got around to small arms, and thus my M29 .44 Magnum.

It gets better, we now have J-frame .357 mags. Not that I would ever shoot one.

The J-frames in .357 Magnum with a 1.875″ barrel must be joy to shoot with full power loads… Too bad snubnose revolvers and other “pocket pistols” are practically illegal here (unless you are an officially certified collector of such pistols).

Your IMA reproduction armor steel chemistry is that of a ‘semikilled’ sinkhead steel produced to commercial quality (CQ). Ingot cast steels of this type are no longer produced by larger, modern steel mills, but some of the small mills in more remote areas still produce sinkhead steels. Think Pakistan.

The nickel in original German armor steel is a solid solution strengthening agent which toughens steel by improving chemical homogeneity. Modern armor steels use less nickel due to its high cost, mechanical hot working is now used to achieve superior toughness.

Silicon beyond about 0.25% is a problem for steel strength due to Bauschinger effect, although this was not well understood during WW I. Same Bauschinger effect is highly beneficial in preset springs, which is why silicon is still widely used in spring steels.

Hello Ian, I recently realized that your video was removed from my WW1 playlist by it being turned private, is there a particular reason for censoring this particular video?

On a follow up question, is your test on the repro armor available on a different video platform?

That is an InRangeTV video, which I no longer have any control over, or access to on YouTube. I don’t know why it was made private – sorry!