The French Model 1917 RSC rifle has a rather unusual gas system, and without some experience it can be difficult to know what one is looking at in one. So today, we’re taking a quick look at how to be sure all the essential parts are in place in an RSC.

Related Articles

Caseless

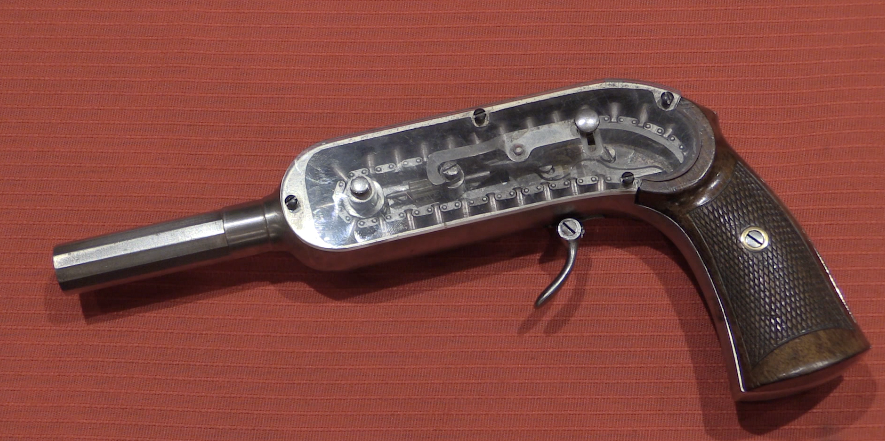

Guycot 40-Shot Chain Pistol (Video)

Prototype

FAMAS Commando Prototypes

Semiauto Rifles

This gas tap looks like inherent weakness of otherwise brilliant rifle. It forces gas flow into awkward 90deg path thus looking lots of pressure to operate piston. Also, this gas screw must have been filled with sooth rather quickly. I know, it is easy to knock on pioneering design; later designers learned their lessons.

…loosing, not ‘looking’

“It forces gas flow into awkward 90deg path thus looking lots of pressure to operate piston.”

How many pressure do you lose vs say Knorr-Bremse m/40? See 2nd photo from top:

https://modernfirearms.net/en/machineguns/sweden-machineguns/knorr-bremse-m40-eng/

Anyway it seems that 90-turn make no problem when properly incorporated, see DP and derivatives.

In fluid dynamics, every turn of piping represents a loss of pressure. If you follow on early gas operated machineguns and rifles, you clearly see attempt to make transition between gas tap and gas cylinder as smooth as possible; typically with angular transition. Lately this part of theory is largely ignored because of ammunition/ propellant infrovements.

In the case we have at hand this problem is aggravated because the gas has to find its was thru randomly located orifice. It goes thru open section back to narrow section in addition to changing direction. This is definitely a detriment to flow.

Here is some visualization from publicly available source

https://www.quora.com/What-affects-the-pressure-on-a-high-pressure-steam-line-if-the-number-of-bends-increases-in-piping

Superheated steam and hot gas have similar flow behaviour.

‘has to find its was’ is supposed to be ‘has to find its way’

I am typing while sitting on floor 🙂

I suspect that the idea was to;

1. Make cleaning the gas block in the field easier; a brush soaked in solvent would clean out any crud.

2. Make it possible to use the Vivien-Bessiere (VB) cup discharger grenade launcher. By simply removing the screw, you disconnect the gas system, and you can fire grenades without excessive back-pressure damaging the piston assembly. Any excess gas just vents to atmosphere.

Still, some sort of retaining lanyard and ring or etc. on the screw would probably have been a better idea. Maybe having it rotating in the end of a flat stamped swing arm about 7cm in length that would allow it to be folded forward and up into a recess on the underside of the nosepiece?

cheers

eon

User-friendliness is always a good thing to have. Unfortunately, some later designs from much richer organizations tossed out end-user-friendliness for sheer coolness and performance in perfectly clean lab conditions (I’m looking at you, US Army Ordnance Corps and British Army “procurement experts”). But back to this rifle: yes, a few things could have been improved, like having a retention arm for that tap-screw as suggested. No need to accidentally drop (and then rummage in the trench mud for) something vital to the operating system of this weapon! Some improvements were done later (clip compatibility and bolt-hold-open latch), and one wonders if making a charger-loaded version in 7.5×54 would have saved France a whole lot of trouble in 1940. Then again, maybe not, as better strategy was lacking.

I am genuinely delighted to have been with this channel long enough to see the man Ian McCollum grow to statistical significance. and then remake himself and his channel in a way that preserves full worth, but allows vital R&R and the kind of more economic logistics that carries a campaign though many years ahead. Well done mate.

Enjoy what you read on Forgotten Weapons?

Your article makes me more experienced and impressed, I hope you will have more good posts in the near future to share with readers.