The Rogak P18 was a copy of the Steyr GB service pistol, with some disagreement over whether it was unlicensed or just unfortunately made. Les Rogak was a Steyr distributor in Illinois who managed to acquire a set of plans for the GB pistol, and put it into production before Steyr-made examples were available in the US. On paper, the gun seemed quite impressive – a stainless steel 18-shot gas-delayed military pistol in the late 1970s was something on the forefront of handgun development.

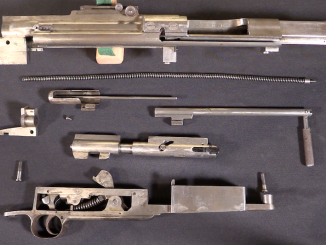

Unfortunately, Rogak’s manufacturing left a lot to be desired. Where the authentic Steyr GB was an excellent pistol (despite losing to the Glock in Austrian military trials and to the Beretta in American military trials), the Rogak copy was quite poorly made. The fit on the gas delay system was too loose to actually hold gas pressure, resulting in the Rogak acting as a simple blowback pistol. To compensate for this, Rogak added a sort of fiber buffer stack in the receiver to reduce the slide battering on the frame, and ground off the extractor claw to prevent the rapid slide opening from tearing cartridge rims off. Numerous burrs, casting defects, and fit problems plagued the guns, to the extent that Steyr actually filed a legal suit to stop their manufacture.

It is commonly stated that about 2300 Rogaks were made, but I suspect the number is closer to just a thousand or so, with serial number ranges being manipulated to give the appearance of greater numbers. While I wold certainly not recommend any substantial amount of shooting with one, they make for a very interesting piece in a collection – guns of this quality are quite rare to find from US manufacturers!

Meta-comment. Is it possible to add the auction house links here on the website?

it is first three words in the video description links to the RIA page

Thank you for the video. I don’t understand from the explanation why it was necessary to remove the extractor claw. If the gun is operating as a blowback or even a delayed blowback surely the case is pushing against the slide and there should be no stress on the extractor (at least, not until the case hits the ejector).

From the video description, it’s not stress on the extractor, it’s too much force on the case head. The extractor’s trying to pull the case out more or less immediately upon cartridge ignition, while (I suspect) the bullet is still in the barrel. Chamber pressure is way too high, and the recoil force is shoving the slide back a LOT harder than it should be. The case body is still stuck pretty fast by the firing pressure, but the extractor’s yanking it out.. something’s gotta give, in the fight between the steel extractor and the (usually) brass case rim, the rim’s gonna lose. Some cases might just deform at the rim (and fail to extract), but most will just have a bit of the rim ripped clean off.

(Correct if I’m reading it wrong?)

Nah. You sussed it: Basically, the original Barnitzke/Heckler und Kock P7/ Steyr design allows for “pressure in the chamber and barrel to safely drop.” Then the reciprocating slide’s extractor pulls out the case that has contracted a bit, and drags it out of the chamer to impact against the ejector, knocking it off the bolt face and out of the gun. In the unsafe faux-delayed mechanism, the extractor claw was tugging on the case while pressure remained high and the case adhered to the interior of the chamber. This stretches the case head, and with plenty of unsafe chamber pressure, results in a catastrophic case head separation.

What I can’t understand, however, was why Rogak left the darn non-functioning extractor in the design? I mean, it doesn’t do anything, so why persist with adding it into the cobbled casting of the slide? Why not eliminate it entirely and make some sort of inflated claim about “not needing” an extractor?

Yes, a clawless extractor from a clueless manufacturer!

It could be as simple as they had a pile of castings laying around when Rogak discovered the guns worked about the same after their extractors broke. Rogak then put the stub extractor in to fill the hole.

Sean E.

On a blowback pistol the only thing pushing the slide back is the casehead. The extractor does not pull the case out of the chamber. The case blows itself out of the chamber. This is why a blowback pistol will work without an extractor. (The HK P7/PSP pistol has a fluted chamber so the case doesn’t just stick in the chamber).

In a short recoil locked breech weapon the slide gains momentum while the case is still firmly locked on the chamber. When the gun unlocks, the slide’s momentum carries it to the rear and the extractor pulls the case out of the chamber. If there is still residual pressure in the chamber the case may want to stay put, and you can damage the case rim or the extractor.

Hopefully that explains my question. If the timing is off on a locked breech weapon I can see how you can get case rim/extractor damage. In a blowback pistol I don’t see it. The extractor and rim are only stressed when the casehead hits the ejector.

I’m a few years late to this one, but I had the same question after watching the video. Instead of trying to justify some sort of delay in the extraction/blowback process I would more readily subscribe to a scenario that Rogak and Co simply saw the rims torn off and ground down the extractor as a quick fix, without doing any other research into the malfunction. My personal theory of the cause of the torn rims would be high cycling speed of the case hitting the ejector.

There are blowback pistols like HighPoint, Astra, VP70 even Llama of latest production and delayed blowback samples like P7, Steyr GB ejecting perfect empty cases after firing. In fact, extractor main function is drawing out a live round from the chamber. Excepting the long recoil handguns and Luger, it is the remaining gas pressure to push the empty case until striking to the ejector. In case of highly fouled and irregular chambers, during extraction, little mass of empty case is beaten by the friction and stops and the slide, by the gain9ed momentum through its big mass, continues its rear movement as shearing off the rim of empty case. If Rogak has such an issue, it should be by cause of the rough, badly cut or large chamber causing a momental stoppage.

By the way, Steyr GB has gas vent holes at the middle of its barrel length, this means, the slide gets free blowback at least for one millimeter and gas brake begins thereafter causing a downward change at reclining elements speed, Occurring one time of such a difference would not make any negative effect on extraction but if this happens repeatedly, the case rim would deform and shear off. The irregularly cut gas piston may cause such an issue.

Strongarm, I think what you are saying is that the case starts out of the chamber quickly, and then gets slowed down, possibly by a rough chamber. The slide then may have enough momentum to damage the extractor or case rim. That sounds possible, but if that were the situation improving the finish in the chamber would be the solution, not removing the extractor. Of course if you have 1000 barrels with dodgy chambers already made, and the bean counters are telling you have to ship the guns, removing the extractor claw may be expedient.

Considering that Rogak didn’t bother to remove the extractor completely, it really seems that they wanted to use all the ready parts, no matter what flaws they had. Probably the whole business depended on getting income from sales sooner rather than later, and without using the defective parts they would not have been able to ship the product at all.

Thanks for your interest James. You have described the happening very well. Seeming Rogak quality precludes the easily improving the chamber irregulaties. It might need to weld inside to handle the correct size and same defects would be also subject for the gas brake elements. Easiest way should be what Rogak had been made. IMHO,

With 9mm Para pistols, the complete weight of slide with barrel is typically at 0.4-0.45 kg (0.8-1.0 lb). If the slide is not locked, the weight needs to be at least twice that much to provide for sufficient delay. With light slide mass, the opening velocity is proportionally higher (by momentum = velocity x mass) and causing problem as described.

It is apparently not commercially tenable to end up with full size 9mm pistol weighing twice as much as common standard just under 1 kg (2.2 lbs). With 2-3x heavier SMG it is not and problem and completely feasible.

“It is apparently not commercially tenable to end up with full size 9mm pistol weighing twice as much as common standard just under 1 kg (2.2 lbs). With 2-3x heavier SMG it is not and problem and completely feasible.”

Additionally 9×19 Parabellum is tapered-case, which might cause problem in blow-back operated fire-arms. I am wondering how Astra 400 (9mm Largo, straight-walled) compares to Astra 600 (9x19mm Parabellum) in reliability?

That is my question too. Well, for one thing Astras are quite heavy… but as far as I know, there is not any mechanical delay included in their design.

Hypothetically speaking, if their chamber has bell-mouth opening (larger in front) it may help with delay. Front part of case is pliable enough to take some extra deformation without bursting.

Reading in Ed Buffaloe’s page I am learning that the slide/ barrel length difference between Astra 400 and 600 was 15mm. I am not quite sure if this allowed for earlier pressure drop (it takes some small delay before slide starts to move) and perhaps that may have been instrumental to concept viability. http://unblinkingeye.com/Guns/Astra_/astra_.html

In the Astra 400/600 series blowbacks, the main resistance to slide recoil was not slide mass but rather an overpowered recoil spring, a direct inheritance from the original Campo-Giro design c. 1904-12. Remember, at that time the dynamics of self-loading actions were still not entirely understood by gun designers (except perhaps John M. Browning), and as such often a designer would take the “obvious” course to solve a problem, rather than finding the not-so-obvious but more effective method.

Considering the penchant of most high-powered blowbacks to open the breech prematurely, regardless of the method used to resist it, I’m surprised more designers didn’t try something like the “roughened” chamber walls of the Kimball to keep the breech closed just a bit longer in each cycle.

Note that while that system didn’t work too well with the high-pressure and high-velocity .30 USC round, it might work better with something like the 9 x 19mm.

cheers

eon

@Eon

Those “roughened chambers” were tried couple of times. Actually, they were annular grooves. I believe Daweo brought one time example of a Russian pistol which was furnished in such manner. But I do not recall where it was mentioned.

@eon #2

Just occurred tome: was there not a 2-piece slide design somewhere, which would gradually accelerate its first part and then gradually second, creating sufficient delay? Maybe I hallucinate….. 🙂

“Russian pistol”

@Denny:

You are probably looking for PMM automatic pistol:

http://gunrf.ru/rg_pistol_PMM_eng.html

“Those “roughened chambers” were tried couple of times.”

Earliest example, which I know is Mann 6,35 mm automatic pistol, made shortly after First World War, see 2nd photo from top here:

http://unblinkingeye.com/Guns/Mann/mann.html

spent cases are marked due to usage of this solution

Later, there was Mann 7,65 mm automatic pistol

http://unblinkingeye.com/Guns/Mann765/mann765.html

(it can be also found chambered for 9×17 Kurz/.380 Auto cartridge), which also retain such “chamber-gripper”, though aesthetic-wise it is closer to Browning automatic pistols.

Some 9mm straight blowback pistols exist, with the Hi-Point arms being an example of a commercially succesful low-cost pistol that actually works. These these pistols rely on a huge slide and keep down mag capacity to keep weight at an acceptable level. If you are into a single action 29oz pistol with 8 shot capacity (35oz for the .45 version), you may check them out 🙂

It is commercially tenable; you forget about the Hi-Point C-9, which has certainly been a commercial success in the US due to its very low price. It isn’t even as heavy as you suggest, since it has a polymer frame. Empty weight is only 25 oz / 709 grams. Of course for a 8/10 shot single column pistol it is still pretty heavy by modern standards, but nevertheless considerably lighter than most historical straight blowback pistols in 9mm Parabellum, except the similarly polymer-framed VP70.

So tell me, what is that “mathematical logic” which makes superlight, dynamically locked (?) Hi-point working. It must be some magic. Once I know I will replicate it and become commercially successful. But I cannot promise I will share with you. 🙂

It’s about the same weight as the VP70. The weight reduction compared to older simple blowback 9mm Para pistols comes from the polymer frame, just like with the VP70. There is no magic, otherwise.

“dynamically locked (?) Hi-point”

Quite weird description for blow-back operated, I would be less puzzled, if it would be mass (like in Deutsch Masseverschluss)

“It must be some magic”

Rather than that, maybe use cartridge, which actually work effortlessly with blow-back principle? Like .380 Auto or 9×18 Makarov?

See for example МР-448 Скиф and МР-448С Скиф-мини here:

http://www.armoury-online.ru/articles/pistols/russia/skif/

Full-size version, firing 9×18, has capacity 12 and mass (without cartridge) 650 g., mini version holds 8 and has following size (length x height x thickness, mm): 150 x 107 x 32 and mass 590 g

More about the Hi-Point C-9: it has only a 3.5″ barrel, which means that the barrel is lighter than in most other full-size pistols and also means that the bullet exits the barrel faster, which reduces the required mass for the slide.

In comparison the Glock 26, which also has a 3.5″ barrel and polymer frame, weighs only 615 grams empty. The Hi-Point also requires less steel parts, which means that all that extra mass can go to the slide. So, in fact there is nothing magically light about the Hi-Point.

In the initial moment after firing, and before chamber pressure rises the case sets back slightly and gives an impulse to the breech face. Here, https://www.forgottenweapons.com/slow-motion-interesting-extractor-problem-schwarzlose-1898/ the slide is moving independently of the case. For them to remain together, there would have to be some stress on the extractor.

The Schwarzlose 1898 is short recoil, not blowback.

True, but there isn’t much oomph in the case once it stops adhering to the chamber walls. If I understand you correctly, this low oomph is enough to cycle the action. Perhaps so, and I am a heretic, but what happens to the case and the slide after the first 50 microseconds (or so) when the the pressure rises and case adhesion to the chamber walls begins? The slide continues to move, the case walls stop and the case head slows considerably, resisted by stretching the case. Have a laugh, just my 2 cents.

Technically, the Schwarzlose is the only “delayed blowback” belt-fed machine gun that actually pulled it off… At least until it was, erm, contrived into an early “above-the-propeller-top-wing-mounted” aircraft MG. It’s got fewer parts than any comparable tripod-mounted MG. Unfortunately, it also requires an oil pump to lubricate the cases before they are chambered. It’s few parts are robustly constructed and few in number. It has just one large and heavy spring. It’s like your knee: It resists the full impact, but then “bends.” The barrel doesn’t move. It is also necessarily short. It used cloth belts, which caused problems in severe cold, you know, like up in the Alps in the “white war” vs. Italy or in the above mentioned aircraft mounts.

“barrel doesn’t move”

This is big advantage, if you want liquid-cooled weapon – much easier than Maxim, where barrels must move but liquid must be not leaked.

“[barrel] also necessarily short”

Not, Czech-upgraded těžký kulomet vz. 7/24 reworked for 7,9×57 mm Mauser has longer barrel: http://modernfirearms.net/machine/at/schwarzlose-m07-12-e.html

“Technically, the Schwarzlose is the only “delayed blowback” belt-fed machine gun that actually pulled it off”

AA-52 machine gun did not?

There was (is?) also the HK21, which is used by the Mexican and Portuguese militaries, among others. Roller-delayed action based on the G3.

bp, What I think you (and strongarm) are suggesting is that the case starts moving very quickly, giving initial momentum to the slide, and then when pressure peaks the case slows down through the case starting to stick to the chamber, but it still has enough reward motion as the pressure drops to blow the case out of the action.

This was my initial thought, and I think it’s possible, but if the case can blow itself out of the chamber, could it fractionally earlier in the cycle get stuck enough to have an extractor damage the case rim? (I really hope that makes sense.)

I suspect we’d have to get some very highspeed footage to see if the case slows down significantly as it comes out of the chamber.

James F, case head separation is an even nastier consequence, especially with higher pressure loads. In the Schwarzlose retarded blowback MG referenced by Dave Carlson above they used oil to lower the chamber wall adhesion. The Pederson retarded blowback guns used wax cases. The Germans used fluted chambers in some of their roller delayed rifles. At 9mm pressure the problems aren’t quite as severe, and below that they are easier to deal with. Something has to give when the case is stuck and the breech face is moving away from it. It could be the case becomes unstuck, the extractor pops off the case, the case or the extractor breaks, or it just short cycles. Again just my 2 cents.

James F, to try and more directly answer your question, I believe the case is stopped in the chamber. What blows it out in Schwarzlose 1898 video is residual chamber pressure which remains elevated long after the bullet is gone. Once the brass contracts enough the gas pressure blows it out. Another point is that lower pressure guns don’t stick as hard and it is easier for the case to be ripped out of the chamber before the brass relaxes. Which does stress the extractor, and then the case catches up to the slide and the gun operates with some extra gas assist as you described in your initial post. YMMV

Apologies. I mistook the reference the Schwarzlose pistol for the MG… “my bad!” For that matter, when I think “Schwarzlose” and “pistol” I usually remember the odd blow-forward pistol rather than the earlier one.

Thanks for the info on the Czech version. You are right, of course, about the French AAT52 GPMG in 7.5x54mm and 7.62x51mm using a fluted chamber and lever-delayed blowback operation. I guess those are chugging along still, although suplemented by the FN Minimi in squads and MAG58 GPMGs in helicopters and so on. Thanks for the corrections.

Your reference seemed odd, but actually appropriate.

The case, at the initial stage, is also pushing against the walls of the chamber.

This (Rogak) is definitely not work of fine firearm production – and is wasted effort altogether.

The original Steyr product is indeed classy case – beautiful with nicely done cast frame and precision machined gas compartment sleeve. Shame it did not succeed in its intended role.

Like Ian said early on: “Rogak” pronounced “Rogue Act…” The welds of the barrel to the frame really say it all, don’t they? Love the Dremel theory!

A perfectly good design can be wrecked by terrible quality control! Another example was the Lorenz rifled musket. The original design was decent, but production by untrained manufacturers (lacking good precision tooling) made standardization impossible! Sometimes the bore would be too large or perhaps the sights were way off target. And then one wondered if the barrel was forged perfectly straight or if there was a kink halfway down where the ramrod would get stuck… Did I mess up?

“terrible quality control”

The origin of problem seems to be also one of “Hey, I can fix it!”-type approach, but in reality “solution” prove to not solve problem.

Quality control comes third after design and manufacturing. If two initial stages were not carried with proper objective in mind, the third one does not help a lot. This is not to say that QC in not that important; it certainly is and its prime task is to weed out out-of-spec parts. I speak partly from my own experience since was involved with steps 1 and 3.

So let’s see here. The initial spec was fatally flawed, the manufacturing process was sloppy, and the firm in question decided to ship out the guns without checking to see that they didn’t self-destruct and/or kill the user upon firing an overcharged test round… And the supposed solutions to the problem of effectively zero gas delay made everything worse. Ultimate solution: STOP CUTTING CORNERS AND GET THE JOB DONE RIGHT THE FIRST TIME! If that fails, eliminate the person who promoted the slipshod project, preferably with a convenient train accident!

Yep, you pretty well got it covered.

“Holy unscrupulous and crummy gun tinkery and patent infringement Batman!!”

I guess that Rogak must’ve thought: “If Barnitzke can’t sue for design infringement and we change things like, say, removing the extractor, omission of the disassembly latch, and using philips head grip screws…Oh, and a European-style heel magazine latch too… We’ll get away with it.” NOT. Seems to me they concocted a pistol that was neither fish nor fowl (but plenty foul, certainly!)

Why not go all out and make it like Gustloffwerke might have? Roll a piece of sheet metal over a solid “bolt” unit held together with rivets and call it the “slide” and then make a rather higher-quality barrel with the muzzle-gas-delay-chamber unit fitted… And use some sort of relatively ubiquitous magazine type. That way you’d make crumminess a “virtue” and appeal to the sorts of people who might buy something like a Hipoint or a Raven or a similar shoddy gun, but offer it in 9mm. Wait, perhaps it can’t be done either… Witness the re-engineeered Gustloff/Barnitzke Volsturmgewehr commanding fully 4 and 1/2 k for the limited production run! Just shy of the price an original one goes for at auction, mayhaps?

Informative video! Perhaps Ian might have a separate segment of his site: “Rightfully Forgotten Weapons!” Heh.

I suspect that Rogak was attempting to piggyback the good name of Steyr Waffenfabrik and trying to make it look as much like a Steyr GB as possible.

I’m wondering if their (very crude) version was copied from a prototype/dealer sample and that’s why it has the weird gas vent/sleeve and the slide was a straight “recasting” exactly like what happens to many fan-made resin movie collectables which get ripped-off by copycats. See “the replica prop forum” for multi-page discussions on recasting.

I can just imagine the advertising pitch: “All the inscrutable design and casual workmanship of an authentic Chinese Mystery Pistol, but made in America by Americans!”

OK… First off, huge caveat here: I can’t document squat, here, and it’s all hearsay that I got at a gun show.

When I was a kid, the Rogak/Steyr GB were “Holy Grail” pistols, for me. I wanted one, in the worst way, but we never, ever saw any of them up here in rural Washington state. So, I was fascinated when I ran into a guy at the Lake County Gun Show circa 1989 who had a whole table/display of Rogak parts in various stages of machining and production, and I was able to talk to him about the guns. Per his story, he was a machinist/production worker at Rogak when all this was going on, and he had a bunch of stories to tell, if you were patient and wanted to listen. Which I was–That table full of parts was like some kind of hypnotic source of fascination for me, at least at first. Taking a closer look at the parts, however…? LOL. Lost any interest in buying anything with a LES stamp on it.

If you look at the Rogak vs. the GB, one thing that leaps out at you is that butt-mounted mag release/catch. You’d think that the Rogak would have the American-Browning standard position, but, no, it’s instead the GB that has that. Queer, no? Well, that’s ‘cos the Rogak is based on an early prototype of the Steyr, along with the less-than-useful gas system, which is purported to stem from the guys at Rogak never really having a solid handle on just how Steyr was doing that–They didn’t get the actual guns or blueprints, just some prototype handling time, a set of half-ass shop drawings, and a vague idea of how it was all supposed to work.

And, what supposedly happened was that the guys behind the Rogak were Steyr distributors who were shown a GB prototype at a time when Steyr was still ambivalent about production–Those pistols went in and out of planning/production something like two or three times before they actually decided what they were going to do with the design. So, the US distributors were shown an early prototype/designs, told they were going to have them to sell, and then… Nothing. So, they were like “Hey, Steyr… You gonna get us these things, or not? We see a market for them…”, and Steyr, through their US sales guy (who was notoriously shady, per my informant) says “Nope, not gonna, changed our minds…”. US distributors ask the sales guy in Austria “Hey, if you’re not gonna build those, can we get the plans/rights to them, and we’ll build ’em here ourselves…”. Shady Austrian sales guy goes “Sure… You betcha…”, and hands over what he’s got, which isn’t a finished set of plans, at all. So… That’s where the primitive nature of the Rogak comes from. There was supposedly some internal Steyr politics going on, as well, and all this was intended to put pressure on the decision-makers to actually bring in the GB.

Talking to this guy, who wasn’t really privy to the “negotiations” over the rights to the pistol, was interesting. I still don’t know how much of what he was saying was true, or whether he was making shit up, but he did have that table full of parts, and things kinda made sense, when talking to him. Inconsistencies and “Hey, WTF…?” didn’t occur to me until well after that day at the show, and I never saw his ass there again.

Another factor here was that L.E.S. was based in Morton Grove, IL. Part of what went into their shut-down was the gun ban the city put into effect, supposedly, but since they didn’t outlaw manufacture, just possession, I don’t know how that would have worked. The gentleman I spoke to alluded to harassment from the city at the “factory”, which was more a half-ass machine shop than a real factory, but there you are.

There’s a mine of flaky goodness at the heart of the L.E.S. Rogak story, and it goes way beyond what Ian’s got here. I wish I could provide chapter and verse, with citations, but I can’t–All I’ve got is a half-remembered conversation over a table full of parts at a gun show back around 1990, and I’m really hesitant to even say my informant wasn’t full of it, either. The whole thing was shady, but it sounded kinda right, you know? It’s like with a lot of things dealing with foreign manufacturers and their US representatives–Toyota, for example, was begged for years to bring in the 4-door HiLux trucks, and steadily told the US branch of the company that they’d never, ever sell–Those were 3rd World products, and Americans would never buy them. That was straight from the mouths of the Japanese Toyota execs, and they didn’t change their minds until Nissan brought in the 4-door Frontiers, and started eating Toyota lunch with them. Supposedly, the Rogak was a part of this–The distributors wanted a Wonder-Nine, knew the market was ripe for them, and when Steyr didn’t turn their vapor into real product, welllll… The guys took matters into their own hands, and we got the Rogak. Supposedly, that was the straw that broke the camel’s back and got Steyr to make the decision to put the gun into production.

And, like I said: All this is pure rumor. Can’t prove a thing. But, it sounds about right, soooo… Who knows? The distributors behind L.E.S. might, if they’re still around. I think the principals are dead, though, so good luck running that down.

Urban, not rural Washington State here… But I thank you very much for the great story, anecdotal evidence or not!

Cheers! I could tell ya about prizing a box of Bulgarian ammo off a gun show display table, only to be tackled by some Bulgarians who told me that it was just a display… Not actually for sale at the show, just something to show distributors in Washington State… “Doh!” Again, thanks!

Iain McCallum is one of the most humorous men on the internet. His humour is so dry and subtle he could be English!

Ian mentions an American Handgunner review that uses subtle language to describe what a POS they were. Soldier of Fortune was a bit less diplomatic, actually dubbing it the “Jamomatic” IIRC. Handgun Tests had an article by the legendarily blunt Phil Engledrum that savaged the piece, he wound up smashing the triggerguard in with a rock and throwing it at the target to demonstrate the ONLY way this pistol was an effective self defense tool…

I have never seen a Rogak in person, but I did find one of the magazines in a box at the Indy1500 gunshow years ago. Ian mentions it won’t interchange with the Steyr, what actually happens is the magazine slides right into the gun. But that little pad on the back that interfaces with the mag release then snaps into the space inside the grip above the nice sharp edge at the rear of the magwell, preventing it from being removed! This was at a time when Steyr GB mags were $100+, I needed a few more, and at the $20 asking price I was willing to see if this Rogak magazine could be modded to fit. After spending 10 minutes trying to get it back out of my pistol, eventually field stripping it and prying it out, i decided it was worth the $100 to get the right magazines.

One must remember LES wasn’t the only company making junk around this time period. Remember AMT’s 1911s? A few years back, I came across a NIB Hardballer Longslide that I couldn’t pass up. Everything in this pistol was absolute crap. Virtually no machining done except surface grinding on the slide flats. The extractor was rod with a groove on one end & a small hook on the other – didn’t resemble a 1911 extractor at all.

I fit the slide to the frame, refinished it, had a custom 7″ barrel made for it ($$$!) and replaced EVERY part in it. It shoots great now, but has a weird recoil sensation: you feel the initial recoil, slide slamming open, then shut in 3 separate events. AMT made this pistol in 10mm (Javelina) & given the poor quality & tolerances, it would probably have been unsafe to fire as originally produced.

If the Rogak was opening before pressure had dropped enough to prevent rim shear, were there any incidents of case rupture & operator injury?

There were others, like the Parker (Wyoming?), but these were unique designs, not knock-offs of other pistols. And the Mossberg CAC45. This was the era of crudely made stainless pistols, but I think the Rogak stands out largely due to the lore of the GB.

There was also the late and unlamented American Arms Aussie, which looked like a hammerless Beretta with its cutaway slide, but was in reality basically an oversized Mauser M1910/34 straight blowback, except in 9 x 19mm. The polymer frame was made of a polyethylene plastic that didn’t react well to heat, cold, firing stress or cleaning chemicals (Hoppe’s No. 9 tended to “eat” it).

The “safety” was a plastic T-bar that swung up from the back of the plastic trigger to prevent it moving backward and searing off the striker. A hard pull would break it, but then a hard pull would break the trigger, too.

The slide was an investment casting of something like the Zamak alloy that Japanese made “non-gun” replicas were made from. And as you might expect, the slide tended to crack after a hundred rounds or so.

The magazine was a fairly brittle styrene-type plastic, and tended to split at the seams after a couple of full load compressions of the spring.

Gun Tests basically destroyed one in firing one box of standard pressure generic 9 x 19mm hardball through it. They said that it was one of the worst pieces they’d ever tested, and advised that it was no bargain even at $199, the going rate when it was introduced.

I think only the EAA Windicator .38 Spl. revolver (which shed its alloy barrel jacket ten rounds into a test) got a worse review from GT. NB; at the same time, G&A and everybody else was raving about the “good value for money” these two fishing sinkers represented.

My opinion at the time was that they had finally created what was known in cyberpunk literature and RPGs as a “polymer one-shot”: a cheap, blowback handgun with a plastic frame, a stamped slide, a ceramic-extrusion barrel, a “capsulized” searage, and a tendency to go full-auto due to sear breakage after about two shots, emptying the magazine-at which point it melts like cheese on a fresh, hot pizza, jamming and maybe even blowing up in your hand. And selling for about $20 NuYen, $100 Euro, or in adjusted USD about $200.

The Wyoming Arms Parker aka Laseraim 10mm was almost as bad as the AMT Hardballer/Javelina, but at least it didn’t generally self-destruct in your hand. It mainly proved that if you wanted a Colt Delta Elite 10mm, you’d best bite the bullet and fork over the $750.

Oddly enough, not all “economy” handguns are bad. The old FEG 9mm P-35 clones used to sell for under $250, and they worked about as well and as long as the “real deal” from FN in Liege’, which were actually made in Portugal anyway. The same for the Argentine High-Power clones of a decade or so ago. I think the difference was that they were made to the original pre-WW2 MILSPEC, with decent QC, resulting in “nothing fancy, but it works”.

Also, unlike FN, they never fell into the trap of trying to shoehorn the moribund .40 S&W into the compact M1935. They realized that (1) outside of the U.S., pretty much everybody used 9 x 19mm, which the P-35 was designed for, and (2) never mind “stopping power” theories, the 9mm P is pretty much all you need for practical purposes.

If you need more than that or a .357 Magnum, you’ve broken Keith’s Third Law; You brought a pistol to a rifle fight.

cheers

eon

“(…)I think the difference was that they were made to the original pre-WW2 MILSPEC, with decent QC(…)”

Also, being made outside of USA, it possibly might be done cheaper, if average wage were lower. Additionally using existing designs, mean that no research & development are needed, which result in saving $$$.

“fit on the gas delay system was too loose to actually hold gas pressure, resulting in the Rogak acting as a simple blowback pistol”

This reminded me about Cargo cult:

https://en.wikipedia.org/wiki/Cargo_cult#Pacific_cults_of_World_War_II

during WW2, pacific tribesmen observed airplanes of fighting sides airdropping and airlifting cargo, which was great wealth, by their standards. After end of hostilities, this activity dwindled, but they In attempts to get cargo to fall by parachute or land in planes or ships again, islanders imitated the same practices they had seen the soldiers, sailors, and airmen use. Cult behaviors usually involved mimicking the day-to-day activities and dress styles of US soldiers, such as performing parade ground drills with wooden or salvaged rifles. The islanders carved headphones from wood and wore them while sitting in fabricated control towers.

term “cargo cult” has been used metaphorically to describe an attempt to recreate successful outcomes by replicating circumstances associated with those outcomes, although those circumstances are either unrelated to the causes of outcomes or insufficient to produce them by themselves

from above-linked query seems to fit, to that automatic pistol, as it tried to be gas-delayed, but fails.

Ironically, Morton Grove, Illinois banned handguns in 1981. It was the first city in the nation to do so. The local law stood for 27 years!

A gun that is best forgotten!

A couple of technical points

The gas bresme (gas “brake”) isn’t to delay opening.

It provides a gas buffer, which allows the slide to be decelerated.

That buffering allow an acceptable weight of slide to be used, along with an acceptable strength of recoil spring.

The comparison with SMG bolts is not entirely valid. SMGs typically have longer barrels, so a heavier bolt is needed in a SMG to allow for that longer bullet travel in the barrel

And, SMG bolts are usually heavier than needed for safety alone, in order to control rate of fire on full auto to around 550 RPM.

“gas bresme”

Gasbremse

I don’t think there is actual difference between “delaying the opening” and “decelerating the slide/bolt” when it comes to delayed blowback guns. By definition no delayed blowback system completely stops the slide (or bolt) movement but only slows it down, sometimes considerably, but still not completely. If the breech remains completely closed with no slide or bolt movement, the system clearly has positive locking, in other words it counts as a locked breech action.

“Delaying the opening” refers to postpone the breechbolt opening when the highest pressure within the chamber exists which occurs only within a few milimeters from the breech and best carred out by the lever or roller delay systems, and “Decelarating the slide/bolt” refers to slowing down the movement of the recoiling breechbolt or slide in all rearward travel to prevent the gun and holding hand to be hardly beaten and also using a weaker return spring for having the same slowing effect at the recoiling elements returning journey all happening alongside the whole rear and fore movement from the breech. Most of the “Gas brake” systems remain in the second category. These two breechbolt/slide downward speed changing are thought to overcome the baddest features of “Straight Blowback” systems and in pistol sized guns, by cause of the relatively short barrels used, only using the decelarating the slide/bolt speed might be sufficient, since the first stage,”Delaying the opening” remains only within a milimeters gap from the breech and the thick web of cartridge case base could tolerate this. AFAIK.

You very au fait with English internet acronyms, i’ve never heard of Afaik- As far as I know.

GTSY Pdb. (Glad To Surprise You Pdb).

Ha ha.

Thank you for the explanation, Strongarm. It makes more sense me now to differentiate between those two variants of delayed blowback.

You welcome, Euroweasel.

Hmmm. Informative comments, interesting pistol. If you were trying to “Volksturm” a GB, in a hypothetical situation in 1945. You’d perhaps incorporate the no ejector idea, casting etc. Profit aside. Crossed with the Jager pistol type manufacturing, and some ideas off the other volksturm pistols you’d probably be getting to… Soviets have arrived armed with bigger guns d’oh.

Perhaps this is based on a WW2 prototype Steyr had, in 1945, too late in 45 so 46 etc, etc. Rudimentary. Then it was rediscovered, and was redesigned. Some of it’s features could be patent avoiding measures alternatively they are just old spec so to speak. The Volksturm gas pistol was very basic, and didn’t really work, this might have been an improvement idea “at the time” The disassembly mechanism seems appropriate for that time.

Heel release. The original Volksturm had ports close to the chamber, but they may have come up with this because of “duration” I mean the Steyr GB moved them to the middle as alluded to above.

It looks old fashioned as opposed a 70’s prototype he copied.

Steyr may have had old documents that they showed him. Which are the origins of the GB albeit redesigned, and this in it’s original form. Even that ejector lark. They wouldn’t have necessarily got that originally either, from that base of new technology E.g. It wasn’t required. Or was but wasn’t. But in the 70’s? Seems odd to me, this pistol. It’s a direct copy of something.

I had a federal firearms license (FFL) for about ten years in the 1970s and 80s. I had one customer who had to have the latest and greatest of everything. He had to have a Rogak and I can confirm that it was a lousy piece of work. The gun was very poorly finished, did not cycle consistently and had terrible accuracy.

This Rogak had a good idea- bleeding the gas closer to the chamber, thus starting the gas action earlier, but it seems that the openings were too small and I suppose the whole gas tube fouled and blocked quickly, that combined with loose gas piston meant the gas delay didnt do sh.t. Only mod. I see is to remove that first gas chamber and allow the gas to directly fill the slide as much as possible (similar to volkspistole idea, but without set screws, lol), that would help with lower pressure.

Ian !!!

Please get a small “narco” pocket scale, and take it always with you on your reviews! We theoreticians here would benefit heavily if you could show us on screen the weight of the Rogak slide, same goes with bolts when doing smg reviews.

I’ve said it before but you never seen my comment I suppose.

Please!

That gives me a higher opinion of Hi-Point. I think I’d always thought the GB and Rogak were the same gun so thank you very much.

I was delighted when I took delivery of my Rogak P-18, because on paper it was a techno marvel and an arsenal in a holster. Delighted! Until I shot it. Gas spritzed out from somewhere, and the damned thing nearly self-disassembled in my hand. I made sure I had all the parts, put it back in the box, and there it stands to this day – a monument to hubris and poor quality. I figured it might be worth something as a curio some day, so I kept it. As I recall, I tried to contact the factory to have it fixed, but no response, so it was keep it or lose everything. I’ve bought die cast Saturday Night Special .22 LR revolvers that worked better.

When this pistol came out, I believed all their advertising crap, so one of my buddies who ran a gunshop out of his barbershop was going to a gun show. I gave him my pristine Luger with matching holster, cleaning kit and spare magazine asking that he trade it for a high capacity 9mm in Stainless Steel. Man was I pissed when he came back with out my Luger and gave me an old Polish Radem in trade. Not being aware of the Radem I told him I didn’t want it, but my Luger was gone, so he gave me an old P17 Engfield in a nice sporter stock with scope in trade, and I walked away swearing to never deal with him again, and I have not.