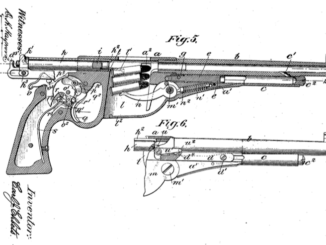

The German military used a lot of different small-caliber pistols during World War One, and the Jäger is one of the most interesting of them. Its unique design was the result of needing to build pistols for the war effort on machines and tooling that were not suited for pistol production. The answer? Replace the single milled frame with a combination of simpler parts that would be pinned and screwed together into a frame equivalent. Quite ingenious.

Now, I have don a previous video on the Jäger, and Othais & Mae at C&Rsenal recently published an outstanding video covering the pistol’s history. What neither of those videos covered, though, was the actual reassembly process. It’s tricky and frustrating, so I figured with a nice Jäger on hand I should document that process.

You can see my previous Jäger video here: https://www.youtube.com/watch?v=VKkUUr4wSrM

You can see the C&Rsenal video on the Jäger here: https://www.youtube.com/watch?v=8kvt9eVQ7d4

Very interesting and inspiring design and thanks for showing it. When comes to C&R, they are simply phenomenal. Good to see all you folks to work together to benefit of us, collectors and enthusiasts. And did I say tinkerers…?

What a cleverly thought out (and unfriendly) pistol

I’m really impressed (with the gun and Ian’s re-assembly)

Did Ian say “national proof?”

it’s “nitro proof” (smokeless).

So it was designed by someone which good know manufacturing process but not good practical usage of automatic pistols?

The purpose of manufacturing such a pistol is realy hard to understand. Frame side plates seem press cut, but lot of machined places inside and out. Front strap with trigger guard and rear strap seem all machined, if not cast or forged. Slide seems press cut and formed but machined inside. Breechbolt seems all machined and slide looks as if formed half sized for the sake of barrel to be fixed high by integral lateral lugs resulting a rather little mass for the cartridge to be used, barrel seems harder to manufacture than the other samples of that age. It is quite possible to form much better designs with the materials and workmanship wasted to built such a handgun. IMHO.

Strongarm, if you watch the C&Rsenal video linked in the description you’ll get an idea of what’s going on here. The gun maker in question was familiar with the construction of double guns built up from die-cut parts. He needed to go into “military” weapon construction to be allowed to continue in the gun making business during the war, so he figured out how to make a “military” pistol using the same techniques used to build their double guns. Thus saving the company from being shut down all together during the “military emergency.” So, what we end up with is an example of gun design expediency rather than practicality.

What did you expect when someone hasn’t got the tools for making single unit pistol frames? If all you’re going to get apart from the barrels is sheet metal, this setup is the logical conclusion.

Exactly, it is much cheaper method. Other alternative is number of machining setups/ fixtures and substantial quantity of end-milling bits, tool grinding capability etc., not to mention machine tools, inspection gages and so on.

Big saving… to say for short.

Thanks for your interest in my post Brian. However, the origin of the author would not explain to form the frame with upward side walls closing the barrel instead of using the same mass into the slide front section and by means, creating a more sturdy inertia against to the recoil and further, simply bending the upper side of frame to inside at barrel base section and thus forming a strong guide for barrel attachment and causing a more simpler barrel free from strange side lugs and further using the recoil spring as cocking support instead of a simple lug at end of the frame, and more further using screws over and there for parts engagement and more and more further some other strange construction forms if to be searched.

A different pistol; Yes… But a clever design; By no means…No!…

By the way, thanks for C&Rsenal for the author related patents. Thus we learned from where the new and innovative O/U double Benelli shotgun genius came from.

Strongarm, I said “gun design expediency” not “clever design.” If you get your hands on some of his Herold guns you’ll see what I mean.

I believe the reason was lower cost. Yourself, being a person knowledgeable of manufacturing processes can easily grasp how long and what effort it takes to manufacture pistol frame by conventional method by chipping it out of block of solid material.

(And yes, I remember seeing process sheets for making HP steel frame.)

Btw, it is likely that this pistol’s side plates are cast (I believe lost wax method of casting was used already then. (Lost was would have saved whole bunch of machining.)

https://en.wikipedia.org/wiki/Investment_casting

Forgot to mention; It was my opinion, not an answer for what you stated. However for an inventor who designed very clever lock engegements to be inspired by Benelli, should be more clever than the merits reflecting in this pistol even if it had been designed within three mounths which is read in Franz Jeager’s biography.

This was such a great video Ian hope you don’t mind posted a link at NCGO.com.

I have to wonder how well a screwed together firearm would stand up under hard military use. I realize that a pistol was more a badge of office than a serious weapon and unlikely to ever come out of its holster, but the trenches were pretty unforgiving places for firearms.