Two of the scarcest and least known of John Pedersen’s designs are the Model GY and GX rifles, which are basically copies of the production model of the M1 Garand. After losing out in the Army rifle trials with his toggle-locked rifle design, Pedersen made one last attempt to garner a US military contract by building his own slightly modified version of the M1. It function the same way as the Garand, with a long-stroke piston, gas port right by the muzzle, and rotating bolt. However, Pedersen put some of his own touches on the rifle, including spiral barrel fluting, drain/cooling slots on the underside of the stock, and a rotating drum to adjust elevation on the rear sight.

Less than 10 of the GY and GX rifles were ever made, and they (obviously) failed to make a significant impression on the US Army – they never went into any type of serial production. This one at Rock Island (#5 GY) is in magnificent condition, and still full of cosmoline from when it was put in storage.

One interesting question I have been unable to answer is, what is the difference between the GX and GY? The folks I have spoken to who have owned or handled one or both have been unable to point to any significant difference. The two designs do have separate serial number ranges (#3 GY and #3 GX are both documented), so it wasn’t just a change in nomenclature after a few were made. One possibility that does not seem to have been tested by anyone is that the two designation use different types of en bloc clip. Perhaps one uses the standard M1 clip and the other uses a clip design Pedersen thought to be better?

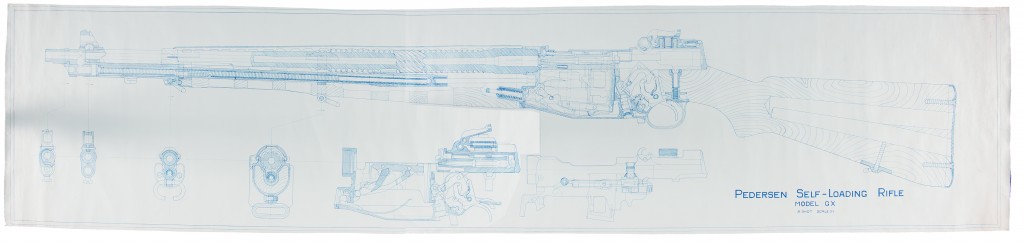

I do have this one diagram of a GX (not a GY), which Rock Island dug up. It doesn’t prove anything, but if you look at the clip drawn in the action, it is a Pedersen type, not a Garand clip:

I work in an Engineering dept. where everything is computer drawn – 2D, 3D – all very cool stuff. Yet I’m old enough to have learned to draw “on the boards”. I look at this drawing and I see a wonderful piece of art. There’s an intent and quality clearly laid out to impress and sell. They don’t draw ’em like that anymore.

For me it is interesting that there we have blue lines on white background, most technical drawing i have seen are white lines on blue background (hence “blueprint” name) or black lines on white background.

That’s because it’s an early-generation Xerox copy. The original was probably black ink on white paper, and the first and second generation Xerography process paper resulted in a copy that looks like this.

(I worked with those things in high school.)

cheers

eon

What Daweo is referring to is ammonia based printing technique and that was in place till 70s. Background was blue, lines were in white – kind of negative to original. One disadvantage was that they bleached out in fairly short time.

Denny beat me to it, but here is some more background. Second job out of high school was running one of those Diazo type machines. One had to turn on a heater first, then turn a knob to set a speed, then take the drawing to duplicate, pull a yellow sheet of paper of the same size out of a (normally dark) flat file drawer, put the drawing on top and run them both through the the first part of the machine (had a light bulb that shone through the drawing) then seperate the drawing from the yellow sheet (now mostly white) and run the yellow sheet through the second part of the machine that exposed it to strong amonia vapors, then the blue line would drop out the back into a bin with the other copies. Switching out bottles of ammonia were a pain, take the cap off the new (strong) bottle and it was not pleasant. In some old offices if you see a ventilation fan somewhere for no reason it could be becuase that was where drawings used to be duplicated. The office had an electrostatic plotter at the time, but it was always too busy to be used to make duplicates, especially when drafting clerks could be had for $4 an hour to run a blue line machine.

I know of some of these still being used in the 1990’s. One selling point was that they could not (fot the most part) be duplicated by the same sort of machine, so if one wanted more prints they had to go back to the company that owned the original. In the mid-1990’s wide format scanner / printers took over.

Blue prints were an earlier technology well before my time. Reading thorugh old magazine articles, it seems like it involved soaking the paper in a liquid to develop or fix it, so while blue prints look neat, the much faster-to-make blue lines must have been seen as a jump forward.

We had such copies when I was in elementary school myself in the early 1980s. The smell was quite distinctive. After I switched schools a couple of years later the new school had a Xerox photocopier, which I thought a great improvement for readability (it was), but it’s those obsolete oddities that make us feel nostalgic when we’re older.

Running an ammonia copier was something of an art, I used about three or four of them through the 90s. even using the ring on a bit of nylon fishing line to cut the paper off, was an art. I used to pride myself on getting the exposure just right – I’d run a few narrow test strips through first to guage what speed to set the thing at.

One time when I was first learning to drive one, I got the air bubbling through the ammonia too fast, and it was amazing how difficult it was to find the door that was right beside me – to escape those fumes.

I think I may have used one as late as the mid two thousands.

Apparently now, businesses are not allowed to get an employee to work one – it’s ok for the business owner to work one if he’s inclined to.

Like Rotring pens, printing stick-on labels, getting the spacing right with stencils and lettraset, and having masking tape on the back of your ruler to lift it off the paper or film, so that the ink didn’t run under it and smudge when you drew a line – ammonia copiers are a lost art.

Pedersen did have several patents for clips and the forming of clips, so it wouldn’t surprise me to learn that his rifles use (or originally used) clips of his own design.

A list of them on can be found here: https://www.google.com/search?tbo=p&tbm=pts&hl=en&q=ininventor:%22Pedersen+John+D%22&safe=active&gws_rd=ssl

“including spiral barrel fluting”

Have this type of fluting bigger area than simple fluting (like say Hotchkiss 1900 machine-gun)? I suspect that simple fluting is easier (cheaper) to machine than this.

What is interesting Pedersen don’t change Bang-type gas-operated mechanism to normal gas-operated. Now it spawn new question: does Pedersen consider Bang-type mechanism proper or he don’t change it due to potential buyer requirements?

“drain/cooling slots on the underside of the stock”

Wouldn’t it let dirt to go inside of rifle?

The spiral fluting could be cut faster on a lathe than conventional right-angle fluting, because the cutter only had to be moved four or five times to cut all the flutes, rather than fifty or sixty times. For mass-production, spiral fluting makes more sense, but not as much as no fluting at all, which was why it was left off the barrels of M1 and M1A1 Thompson SMGs.

Cooling slots on the underside do indeed act as dirt scoops when firing prone. This is the reason that the forward stock section of a Garand has that huge open slot under the front half of the gas tube. It allows plenty of air circulation around the hottest part of the tube (just aft of the inlet from the barrel), but doesn’t allow dirt to accumulate; it just falls back out, usually literally shaken out by recoil vibration.

cheers

eon

I am sure the thickness of barrel is substantial enough to counter pressure, but still, this kind of operation does leave notches which act like potential stress risers. Since in closed tube the radial stress is twice of axial, it might be wiser to go for radial type albeit it entails more machine time.

If you were cutting it on a lathe, you’d need to drive the leadscrew. which is possible but a pain in the arse.

any attempt to cut a helix with a longer pitch than the leadscrew by driving the spindle, will result in broken gear teeth in the gears between the spindle and the leadscrew.

It’s much more likely to have been cut on a milling machine with a universal dividing head gear driven from the table feed, and some combination of the table and / or the cutter being angled to match the helix, for example in the eighth photo down here (which is from the right time period and a good candidate for the type of machine used) http://www.lathes.co.uk/cincinnati/page7.html

for anyone who’s into milling machine accessory porn, these guys from the next lake accross from where Fiocchi cartridges are loaded – really were great, there’s even a set up to make a mill into something resembling a Bilgram gear shaper, to generate the correct octoidal tooth form for spur gears http://www.lathes.co.uk/riva/page9.html

One thing I see (and there would be more upon closer examination) is that on GY model, the charging handle is disproportionally small. This is not what you want to put in soldier’s hand, day-in day-out.

Agreed. It’s difficult to grasp a small charging handle under stress and even harder if your hands are wet. Grabbing a small charging handle gets worse if you are shooting at some bad guys in some rather nasty winter conditions.

I suppose the Pedersen Garand would still beat the Japanese Type 5 if the two ever met… Or would it? [ominous music, please]

“is that on GY model, the charging handle is disproportionally small”

For me that suggests that the GY is earlier than GX, inversely than alphabetical order would suggest (X later Y)

” I look at this drawing and I see a wonderful piece of art. There’s an intent and quality clearly laid out to impress and sell. They don’t draw ‘em like that anymore. ”

tom: look this: a real design masterpiece:

https://www.forgottenweapons.com/wp-content/uploads/Mannlicher%20pistol/mannlichercarbinepartssmall-300×220.jpg

https://www.forgottenweapons.com/wp-content/uploads/Mannlicher%20pistol/mannlichercarbineparts.jpg

(mannlicher carbine)

and this:

http://s019.radikal.ru/i602/1205/e0/67141c559ecf.jpg

(napier sabre engine)

Wow….more than a few hours on that engine drawing. On all of them actually. Thanks for posting these links.

Do you have any information on the weight difference between the Pedersen GY and the M1? The GY seems like it would be even heavier than the M1.

The thing holding back the Garand (at the time) was that it was not the easiest gun to manufacture. If someone was going to suplement or replace the rifle the objective was to make something that was eaiser to make (e.g. the Johnson rifle). This rifle, if anything, may have been more difficult to manufacture.

The vents and cooling fins would have come in handly once, Medal of Honor winner Hector Albert Cafferata, Jr. reported that the handgaurd on his Garand caught on fire several time and had to be put out with snow during his several hours long fire fight at the Chosin Reservoir in Korea.

All Pedersen designs seem over detailed alternatives for existing more simpler samples of same secure, robustness and functionablity. There are brilliant touches of ingenuity over and there, but not being preferable to more practical specimens. Most brilliant of them,

seems, Toggle Delay System which is an engineering miracle as similar as old time rotating drum VCRs being unbeliveable seeing as a working machine coming from intriqued, complex, hard to understand thoughts inked down into drawings of common paper.

“All Pedersen designs seem over detailed alternatives for existing more simpler samples of same secure, robustness and functionablity.”

I guess that was caused by fact that simpler methods was just patent and Pedersen design his fire-arms to avoid patent infringements. Notice that most Pedersen weapons was preceded by other designer patents for this class of fire-arms; Examples:

.22 rim-fire pump-action rifle:

Remington Model 12 (1909) – Winchester Model 1890 (1890)

12 gauge pump-action shotgun:

Remington Model 10 (1908) – Winchester Model 1897 (1897)

.380 Auto [9x17mm Browning] automatic pistol:

Remington Model 51 (1918) – FN Model 1910 (1910)

Anyway Pedersen had not luck with military contracts – only mass-produced military weapon of his design was Pedersen Device turning M1903 rifle in self-loading rifle firing smaller .30-18 cartridge, but it was late for WW1 and so far I know was never used in combat.

This may be a stupid question, but wouldn’t Pedersen have run afoul of patents on the Garand with a design so close?

Hmm…I’m not sure.

Since Garand was working for the government, it is likely that the government owned any patents he made. If the government had decided to adopt Pederson’s rifle, then I doubt the government would have sued the government for infringement. On the other hand, it might well have prevented Pederson from marketing the rifle to any entity other than the government if Garand had filed for patents. Might being the operative word, as the Mondragon rifle may have precluded some claims as being prior art under utility patents, and I doubt that Garand ever filed a design patent on the overall appearance of the rifle. Some of the unique items on the Garand, Pederson did not copy (the rear sight, the exact trigger double sears, etc.)

I did notice that the follower and follower arm seem to be of different. Single on the Garand and Dual on this diagram. Might force the redesign of the clip.

That bolt looks way different to the Garand one, and the receiver doesn’t have that huge gap that’s on the M1.

I wonder how that one would’ve performed in the tests.