I’m very happy to present another guest article by Leszek Erenfeicht today, on a very rare and quite unusual Polish submachine gun from the years just prior to WWII. As always, Leszek does a great job describing the mechanics and history of the weapon…so without further ado:

Mors wz.39: Poland’s Deadliest SMG That Never Was

by Leszek Erenfeicht

In the early 20th Century the Europeans have still been teaching their youth classical, long dead and gone languages – Latin and old Greek. As a result many technical inventions originated then, bore Latin- and Greek-derivated names – television or bathyscaphe being just two examples. Two most renown Polish pre-World War II gun designers, Piotr Wilniewczyc and Jan Skrzypinski, also christened their designs with Latin names. While every other gun lover at least heard of, if not actually handled, the wz.35 Vis (Latin for “Power”) pistol from Radom, their other 9 mm design with a Latin name remained hitherto almost unknown. It was the submachine gun they called the Mors – Latin for “Death”. In reality though it turned out to be not that deadly at all…

How the Death was Born

Many inventors were proposing the SMGs of their design to the Infantry Board of the modernizing Polish Army in the early 1930s. Of these, a project by Skrzypinski and Wilniewczyc, blowback operated selective-fire weapon with a quick-change barrel feature and vertically positioned magazine, was chosen for further development.

Their project, when executed in metal and put to various tests, proved to suffer from excessive cyclic rate of fire (over 1200 rpm). Due to that, its 24 rd magazine capacity (governed by a size of the 9 mm military ammunition pack tailored to the Vis pistol ammunition allowance of three 8-round magazines) only lasted for a 1.25 sec of fire. With this excessive cyclic rate also came the excessive dispersion of hits. Nevertheless, the military testing board saw some merits in the weapon and recommended alterations to be made.

These were implemented by a team of young designers from Warsaw’s Państwowa Fabryka Karabinów (PFK, the State Rifle Factory), headed by Wilniewczyc and including Feliks Modzelewski, Jerzy Podsendkowski (later to create a revolutionary compact MCEM 2 submachine gun, that greatly influenced the design of the Uzi), Waclaw Dworzyński and Jan Potyński. They were redesigning the weapon according to a new specification, basing on the results of the comparative tests of several European SMGs, staged by Instytut Techniczny Uzbrojenia (ITU, Ordnance Technological Institution) at the Infantry School in Rembertów, suburb of Poland’s capital Warsaw, during the spring of 1937. Among the SMGs tested to establish characteristics to be embodied in a new weapon were German Erma EMP, Finnish Suomi KP/31 (used by the Poland’s State Police since 1932), US Thompson M1921 (used by the State Police since 1926), and Swiss SIG-Neuhausen copy of the Schmeisser’s M.P.18,I. The Erma was found the most suitable for infantry use, with only the side-protruding magazine to blame.

The second, improved prototype, and the first to be called Mors, was made at Warsaw’s PFK and put to tests at the Instytut Badań Balistycznych (IBBal, Ballistic Research Institute) in Zielonka near Warsaw. At the same time, in mid-February 1938, the design was patented (Nr 56 390) – but unfortunately, no copy of that patent survived the ravages of war. The only document dealing with this, and subsequent patent 61 051, pertaining to the pneumatic rate of fire reducer of April 14, 1939, is a patent rights purchase contract signed between the PWU-FK and the designers.

Upon completion of the very thorough test program, a comparative test with the EMP was staged in April 1938. The test board found accuracy in both semiautomatic and full automatic fire ‘unacceptable’, blaming it on the barrel shorter than the EMP’s (210 mm compared to 320 mm). The initial velocity was 12 mps (36 fps) lower than the EMP. Test shooters complained about front sight blade being too wide and rectangular in section, contrary to the inverted V they were accustomed to. The sighting radius being shorter than the EMP’s, and loosely fitting quick-change barrel didn’t aided in accuracy, either. Cyclic rate of fire was lower than with the former prototype, but still deemed excessive at 750 rpm, compared to the EMP’s 520 rpm. An “excessively stiff” return spring and “too short” (109 mm compared to 120 mm in the EMP) bolt travel were blamed for the high rate of fire. “Excessive length” of the stock and “wrong position of the foregrip”, were found guilty of weapon’s uncontrollability in full automatic fire. Placement of the foregrip, too far forward for the average shooter, was dictated by the magazine well being incorporated into it. It is an idea worthy of a note, as it came back with the Podsendkowski’s revolutionary MCEM 2 of 1944, where the magazine well was also incorporated into the grip – but this time it was the pistol grip, the only one that weapon had.

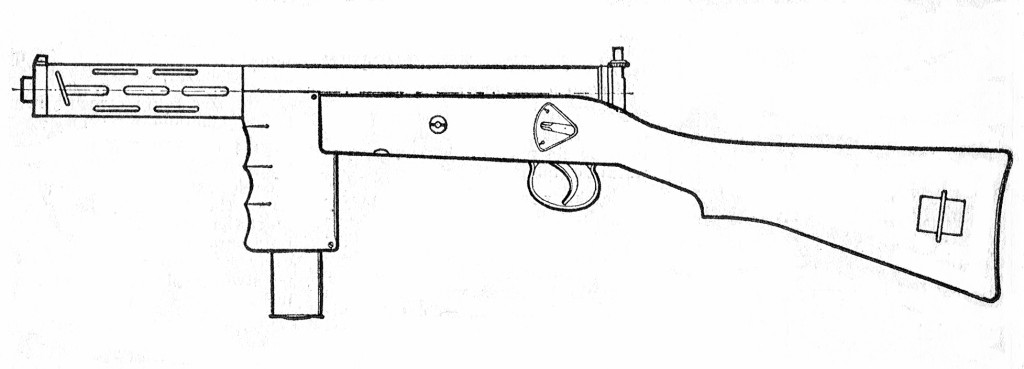

The first Mors was therefore not an excessively impressive weapon, but not a complete failure, either. The test results drew attention of the Inspektorat Broni Pancernej (IBPanc, Armored Troops Inspectorate), long searching for a prospective firearm to arm the tank crews. Their mainstay at that time were the two-man TK/TKS tankettes armed with a single 7,9 mm Hotchkiss wz.1925 MG, a Polish-improved version of the British Vickers Carden-Loyd one-man tank, in which a trooper hardly had space to sit properly, let alone handling any decent weapon. As long as he was actually able to sit in his tank, that was not a problem, but after being forced to bail out, the only means of fighting his way back to the lines was a mere pistol. Even with a pistol as good as the Vis (known as a ‘Radom pistol’ elsewhere) was, this was much too little of a weapon to call it a good idea. The IBPanc wanted a compact SMG, but there were no any to choose from at that time. Instead, in 1932, they proposed to add shoulder stocks to the Vis pistols, then in 1936 commissioned the Radom factory to make them fire fully automatic. The stocked pistol-carbine idea was bought by the Infantry Board, and all Polish-made Vis pistols were cut to accept the stock-lug. On the other hand, though, the Infantry Board was definitively against the machine-pistol idea, and the project was never finished. Then the IBPanc got a word about the PFK-designed submachine gun and abandoned the stocked machine-pistol project, backing instead the “true” SMG program. The first Mors appeared to be just what the doctor prescribed – an 828mm (32.6in) long burp gun, quite compact for the era, needing only what seemed to be a slight de-bugging…

The Mors test minutes were forwarded to the PFK and these resulted in the delivery of the two further improved variations (called ‘Model No 1’ and ‘Model No 2’) of the third, completely redesigned prototype, called the “Mors 2.” Nos. 1 & 2 differed in trigger mechanism, sight arrangement and magazine catch designs. Based on the comparative tests of the two, the No 1 model with a fire-selector lever was rejected, while the No 2 with dual triggers (influenced by the French Chatellerault 24/29 LMG, just like in the case of the contemporary Beretta M1938A) was to be further evaluated. The semiautomatic accuracy improved much, due to a longer (270 mm), more tightly fitted barrel and redesigned sights. The initial velocity was now barely equal to the EMP. A weaker mainspring coupled with increased bolt travel reduced the cyclic rate to about 600 rpm. The stock was redesigned, the fore-grip separated from the magazine-well and moved back, towards the center of balance, then drilled through and fitted with a Vollmer-style telescoping monopod. Nevertheless, the dispersion was still 40% higher than the EMP’s. It was much better than the former prototype, shooting 200 – 300% wider groups, but the dispersion in full automatic fire at a distance of 200 m was still 300% larger than that of the EMP. The vertical dispersion in burst fire was especially large, and ironically, grew even larger, when fired from the very monopod meant to stabilize it. The Board blamed it on still excessive rate of fire and lower, poorly balanced, weight of the weapon. The Mors 2 was indeed 690 g (1.5lb) lighter than the first Mors (3.95kg/8.7lb versus 4.64kg/10.2lb) and 520g (1.15lb) lighter than the EMP. The test minute recommended reduction of the cyclic rate to 500 rpm and increase in the weight of the weapon back to about 4.5kg (9.9lb), possibly by using a heavier barrel to both aid in controlling muzzle-climb and dissipate the heat.

The all new, fourth prototype, called the Mors 3, embodied all of the above recommendations. A batch of three prototype sub-machine guns with three magazines each were ordered from the PFK with delivery scheduled for January 10, 1939. These were put to various tests. The rate of fire was recorded decreased to about 450 rpm due to the use of the pneumatic rate-reducer, slowing the bolt travel. The new gun was accepted by the Komitet Zakupów Uzbrojenia (KZU, the Ordnance Procurement Board) which placed an additional order with the PFK for a test lot of 36 units of the “9 mm pistolet maszynowy wz. 39 Mors” (or “9 mm M1939 Mors sub-machine gun”) for the troop trials. The delivery of guns, each priced at Zloty 2500 (then roughly $500), was scheduled for April 15, 1939, but actual delivery was postponed to June 3, 1939. The troop trials were conducted by 39th Infantry Division, Military Police units and the 3rd Rifles Battalion in Rembertow.

The introduction of the Mors 3 was a major blow to the tankers. What begun two years earlier as a 828mm (32.6in) long SMG, now concluded in a 970mm (38.2in) weapon, only about an inch and a half shorter than the wz.29 Mauser rifle, long ago considered unsuitably long for tank crews use. They had to beat a hasty retreat to the stocked pistol idea. Vis wooden holster-stocks, that all the Vis pistols were cut for but which never before were issued, finally were designed in early 1939 but no hard evidence of their actual issue survived. In early 1990s Thomas B. Nelson of the Collectors’ Armoury Ltd. commissioned a batch of these to be reproduced in Poland, and reportedly got into much trouble with the BATF, not convinced that these were indeed replicas of the actually existing accessory.

As the PFK has already tooled-up for serial production of the weapon, it is highly probable that it was continued during the siege of Warsaw, and several more Mors were made, presumably for the forces defending the capital. No any data is available however to support or to deny this hypothesis.

The Hunt for Mors

For a long time after the war the Mors SMG remained half-legendary, esoteric weapon, that everybody in Poland heard of, mostly only in superlatives, but nobody knew about for sure. Much confusion was caused by Mr. Wilniewczyc’s own publication in Vol.1 (1959) of the ‘Muzealnictwo Wojskowe’ periodical issued by the Muzeum Wojska Polskiego (MWP, Polish Army Museum) in Warsaw. In the said publication the sketch of the original Mors with a short barrel and fore-grip encompassing the magazine-well, was published as an illustration of the production model, misleading many researchers.

After Mr. Wilniewczyc have died of cancer in 1960, the nation-wide hunt for the Mors begun but it was only in 1983, when the first two were found in Moscow’s Central Red Army Museum. No any paperwork was preserved with them – the only records shown that these came to the Museum from the Red Army’s small arms research institution during the 1950s, together with about 100 other weapons. It is unknown whether these were captured by Soviets from the Polish or German troops. The two guns bore consecutive serial numbers – 38 and 39 – which suggests that these were taken from a warehouse rather than from the field troops. Also, the numbers tend to suggest that these were the last examples of the 36-gun batch ordered on top of the three Mors 3 prototypes.

The s/n 38 Mors now on display in Warsaw’s Polish Army Museum is preserved in fair condition, except for a missing magazine, tangent sight leaf, broken trigger mechanism springs and a mock barrel, closely patterned after the barrel of the s/n 39 still in Moscow. A tapered muzzle with a perpendicular undercut suggests that some kind of muzzle-device was provided, but there is no trace of it in preserved records.

A third example, s/n 19, was recently uncovered in the St.Petersburg Museum of the Artillery, Engineers and Communication Troops. Interestingly, although the serial number is 20 numbers apart from the Moscow ones, it also lacks the magazine and tangent sight’s leaf. The other interesting omission is the foregrip with the monopod. This missing item was found on…an 1950 experimental Kalashnikov AK-47, 1st Variant, pictured in the book ‘Kalashnikov Arms’ by Yuriy Natsavaladze and Boris Paranin, pp. 56-57!

The Pros and Cons (Mostly Cons) of the Mors

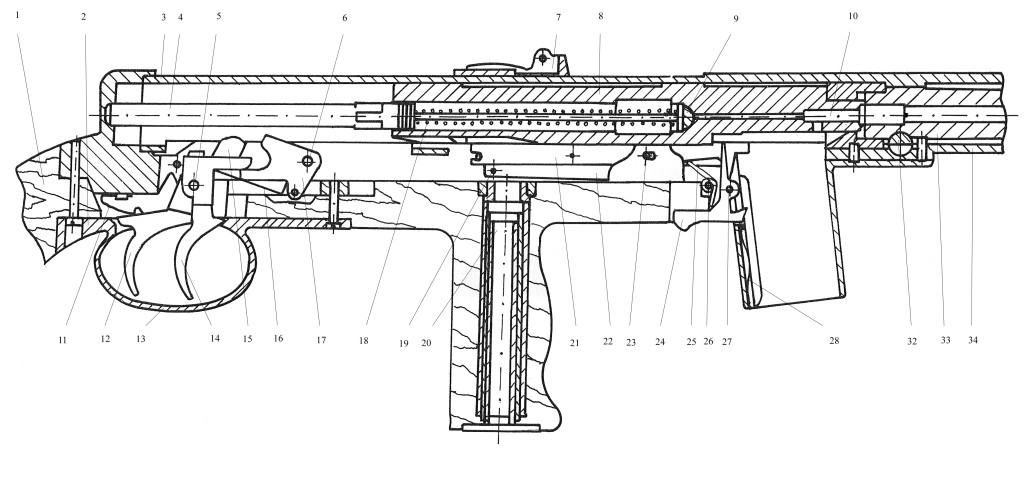

The Mors wz.39 was a blowback sub-machine gun, firing from the open breech, fitted with the dual-trigger firing mechanism, quick change barrel, hold-open device coupled with a lever automatically releasing the empty magazine from the catch, pneumatic rate of fire reducer, and telescoping monopod. No further bells and whistles, and this author found the lack of a little fountain particularly disappointing.

The monopod is placed at the unloaded gun’s center of gravity – it will stand on it without additional support. During firing it was reported to aid the muzzle jump – just like in the Vollmer’s Erma EMP, from which it was copied. The monopod itself consists of three sections, one of which is permanently attached to the gun and serves as an axis for the foregrip. The other two telescope one into another, and the one of the least diameter has a rounded foot at the bottom. This foot also aids in retracting the monopod from the foregrip. It’s a tough task, as the pieces of the monopod are fitted very tightly together. Five times out of six you’ll tear the whole thing out of its socket instead of extending it. With some training you’ll learn to pull only in short strokes – let go of it immediately after you feel it moved! Otherwise you’ll finish with movable parts of the monopod in one hand, and the gun in your other. It is also as tricky while shoving the damn thing back. You have to find the little tongues with projections on their ends, resting under the rim of the wider tubes, depress them to hide these projections and then push the inner part in until the next stop. Then locate another pair of tongues and repeat the process. After you try to do it once, even without the opportunity to fire the Mors with the monopod, you’ll have enough of that for a lifetime.

Atypical for a weapon so full of gadgets and gimmicks, there are no safety devices other than the L-shaped cutout in the right rear part of the receiver. This at least works as in much other SMGs of the era – you have to retract the bolt past the sear and rotate the cocking handle into the slot, thus blocking it to the rear.

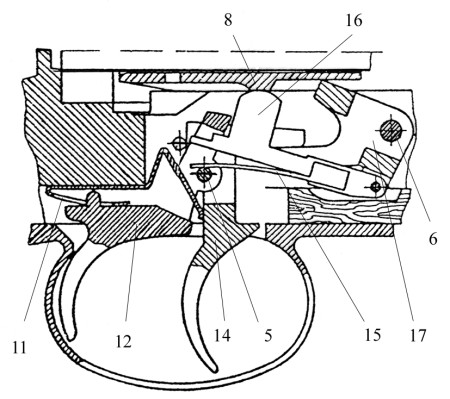

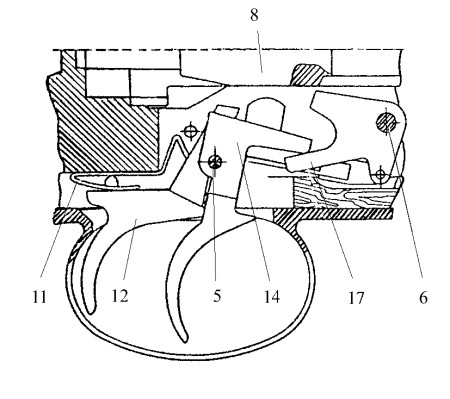

The trigger mechanism uses separate triggers for semiautomatic and full-auto fire. In the accompanying drawings the trigger spring [11] shape is hypothetical, as it is broken-off and only a stub of it survived. There should also be some kind of a sear spring, but this one is missing either. Pulling on the full automatic (forward) trigger lowers also the semiautomatic trigger, but the full automatic trigger remains in position when the semiautomatic trigger is being pulled. The disconnector [16] functions during the rearward travel of the bolt. The hold-open device incorporates as many as 10 (ten!) parts and is overly complicated even by then popular construction standards.

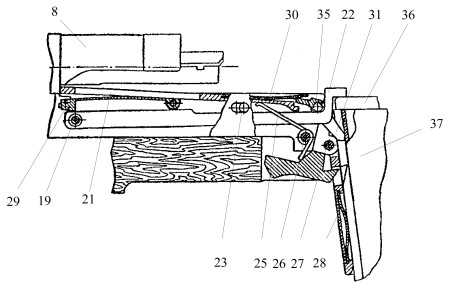

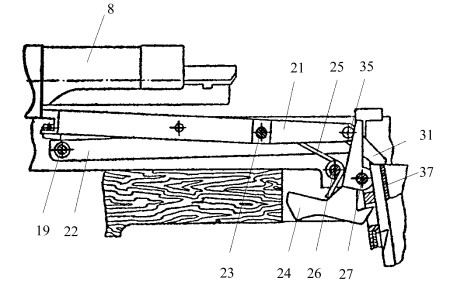

It operates as follows: The follower of the empty magazine raises the right arm of the lever [22], which in turn pushes the left arm of the hold-open [21] upwards. The bolt, traveling forward strikes the hold-open, pushing it about 3 mm forward, due to oval hold-open shaft openings in the walls of the trigger group housing. This movement pushes forward the auxiliary magazine catch [31], rotating on shaft [35]. The shaft [35] in turn acts on the upper arm of the magazine catch [24], thus disengaging it from the magazine [37]. By the way, this is about the only way to disengage the catch – it is flush with the stock and needs a narrow object being inserted into the opening to let the magazine go! The empty magazine cannot fall out freely, because it is held in the magazine well by both the auxiliary catch [31], actuated by the flat spring [30], and the flat magazine retaining spring [28], but it can be withdrawn without any further manipulation. Removing the magazine will allow the auxiliary catch [31] to drop to a position in which the newly-inserted magazine will push it upwards thus raising the right arm of the hold-open. This will in turn disengage the left arm, allowing the bolt to go forward a few millimeters, until the sear engages, and the gun is ready to fire again. The magazine catch spring [25] will return all the parts to the battery. Pretty tricky, isn’t it?

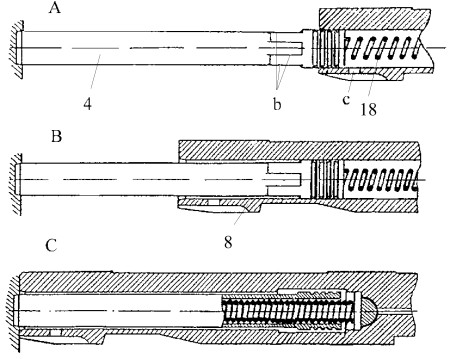

The pneumatic rate of fire reducer operating principle is also shown in the diagram. In extreme forward and rear positions the vents [b] and [c] will allow the air to bleed out, but during the movement of the parts those are sealed. During the forward travel a vacuum forms, and during the rearward stroke the air is compressed, in both cases slowing the action. Due to the non-shooting condition of the preserved gun one cannot establish how is this device really effective, but even while cycling it with a hand, one can hear the air hissing while being sucked in and blown. For the actual shooting results, we have to relay on the January, 1939 test minutes, claiming the rate of fire in the vicinity of 450 rpm. How would such a precisely machined device operate in real field conditions, we can only speculate.

The quick change barrel feature is one of the most doggedly discussed points of this gun. Ignoring the actual tactical virtues of the quick-change barrel design in a sub-machine gun (or rather, the lack thereof), the solution used in Mors is very far from ideal. In theory, all you have to do to remove the barrel, is to rotate the barrel change lever/disassembly pin clockwise through 180 degrees and point the barrel casing down. The heavy bull-barrel should drop out under its own weight. This author came to have some serious doubts about the good sense of the designers. In reality it still needs a hefty jerk of the weapon to disengage and fall. And you better watch your feet doing this stunt, as the barrel is heavy with sharp edges. I managed to punch a 2-3 mm deep mark in the heavy oaken floor boards of the museum’s warehouse, earning dirty looks from the otherwise very friendly museum staff! And this was with a cold barrel – what about a red-hot, heat-swollen one? Re-inserting is tricky, too. There is a narrow re-aligning post buried deep inside the barrel bushing, which you have to align with an equally narrow slit in the barrel. In theory that may sound OK, but then again in reality, the post is positioned so deep, and the slit is so short, that one can only pray to re-align the barrel properly with a first drop. If you miss it, the barrel sticks inside the casing, and suddenly all you have above the rim of the barrel jacket to catch onto and try to rotate it into position is a conical-shaped muzzle, roughly a centimeter of it. There are special openings in the bottom of the barrel jacket to assist in aligning the barrel – but they are of little use after dark. The whole barrel change process is a slow one and requires a lot of attention from the operator – a total “no-no” under actual combat condition. Thank God hardly any of these were actually issued prior to the September 1, 1939 German invasion!

Sticking to that useless feature in the ultimate production model makes one wonder about the reason of the people who made this decision. For one, with the ammunition complement of three full magazines, or 72 rounds, it is impossible to render the thick, almost half a kilogram heavy bull barrel hot enough to require a change. The equipment list provides no magazine filler, so after shooting these three magazines, the shooter had to spend so much time loading them again, that the barrel would cool down completely by itself. Second, the barrel-changing procedure is so complicated, that no one would be able to perform it under the battlefield stress, in the dark. And finally, third – this is an open bolt weapon, bolt stays open between bursts, so even in the unlikely event of overheating the barrel, there would be no accidental discharges due to cook-off – so indeed, why bother? And they didn’t in fact – the June 1939 dated equipment list for the Mors shooter lists one pouch for three magazines with a carrying strap, one SMG carrying sling, cleaning kit, three magazines – and that’s it. No spare barrel pouch, no spare barrels. The reason (well, some semblance of it, considering reducing ready ammunition supply to mere three 24-rd magazines) had finally prevailed.

Field stripping

On the other hand, the field stripping is very easy and straightforward – the barrel change lever [32] upon turning counter-clockwise through 90 degrees can be withdrawn completely, freeing the receiver from the stock. The barrel can be now drawn out, and bolt together with the return spring and rate-reducer tube would slide off the rear end of the receiver. The end of the return spring guiding rod fits into a cut-out in the rear of cocking handle, thus locking it inside the assembled bolt group. Upon withdrawing the mainspring group, the cocking handle is free to be taken off, thus freeing the bolt to be withdrawn from the receiver. Two screws secure the trigger housing to the stock. Further disassembly is neither recommended, nor needed, except for repairs.

Technical data 9 mm Mors wz.39

Length: 970 mm / 38.2 in

Barrel length: 300 mm / 11.8 in

Weight, unloaded: 4.25 kg / 9.4 lb

Rate of fire: 450-500 rpm

Sight settings (m) and type: 50-600 tangent

Thanks for a highly-informative and well-written article on a largely-unknown and technically-fascinating weapon. If there is only one known complete example of the Mors wz.39 in existence, it is probably the rarest such firearm in the world today.

Earl, thanks for the praise, and all. One clarification: s/n 38 is sole POLISH survivor, not a sole survivor at all, as clearly listed in the article. There are two others (s/n 19 and 39) guns preserved in Russia, and a fourth, also incomplete (as far as smartphone photos thru a museum glass cabinet tend to show), has been recently reported from Budapest, Hungary (s/n so far unknown).

Thanks, Leszek. I was referring specifically to a lone surviving complete example of the gun in my comments, of which the Polish gun appears to be the leading contender. Re-reading your article for clarification ( in case I had missed something ), the other Mors wz.39’s appear to be more incomplete, and therefore less viable. Sorry for the misunderstanding:).

Either way, this still makes the wz.39 rare to the point of being at the top of the “rarest” list.

Had a chance to handle one of these SMG-s in the Museum of Military History in Budapest. It is a weapon that was taken from the Polish soldiers harbored in Hungary before they were allowed to leave for the West. It is missing the bolt and recoil spring assembly, probably thrown away by the Polish soldier before surrendering the weapon to the Hungarian troops. Looked like a well made, if a little bit awkward weapon.

Great article !!! Best thing that happened today 🙂 Thank you Leszek and Ian.

It is quite surprising to read about initial high rate of fire, given length od gun and namely its receiver’s. The MP-38/40 was comparatively low at around 500RPM http://www.mp40.nl/index.php?page=mp38

The PPS-41/43 again was notorious for high rate of fire. When you look at both MP and Spagin you find fairly low weight bolt assembly. What apparently made such difference was bolt’s length of travel. One has to bear on mind that those were pioneering days of SMG. The presented material is meticulously compiled and deserves admiration.

Whoa, hold your horses – the excessive ROF was with the early prototypes of the Polish SMG, and both bolt and receiver has been greatly elongated since then. The bolt photo shows the last stage, when the ROF was reported to have fell to a mere 450 RPM, which is the opposite end of the range for the SMG. And MP 38 might have had a short bolt, but is wasn’t the whole mass the spring had to overcome – add the whole bicycle pump arrangement inside, and the weight almost doubles. Yet you’re right that it is the length of travel that rules the ROF. I don’t quite gather the ‘PPS-41/43’, as this handle covers two very different Soviet SMG, the Shpagin PPSh-41 and Sudayev’s PPS-43. The PPSh-41 cycled at over 1000 RPM, while the PPS-43 bolt, although only 15% heavier, cycled at mere 600 RPM with no other gimmicks than a long empty upper receiver. The length of travel increased almost 150% – and that was enough to slow it down considerably.

Spring weight and spring rates are also factors in the cyclic rate of a blowback-fired gun, as is advanced primer ignition. But you’re right that the bolt weight and the amount that it moves before being returned by that spring are the most important factors. A truly great article, Leszek. Bardzo swietnie!

A scholarly effort! Thank you for a particularly informative article.

Most industrial pneumatic cylinders (present in most assembly machinery) have something similar in principle to the “pneumatic rate of fire reducer”. In pneumatic cylinders they are referred to as “cushions” or “cushioned ends”. They are intended to reduce the impact shock at the end of stroke (if you make use of the full stroke of course). They work quite well and rarely give trouble. I don’t know when these became common, but anyone today who has any familiarity with the design of industrial machinery will be know about them.

However, an SMG has to operate in a much more difficult environment than a pneumatic cylinder, and I would be concerned about it getting gummed up with dirt (mixed with oil). I don’t know if any other firearm has used the idea successfully, so I suppose it is possible that this concern is misplaced.

As for the quick change barrel, I think that another SMG also had one, but I can’t recall which one that was. As you say though, the feature is rather pointless in a weapon of this nature.

I know the Hyde carbine for the M1 Carbine competition had an MG 42 style quick-change barrel for some reason.

The Suomi had both a quick change barrel and an adjustable air vent at the back of the receiver tube. http://guns.connect.fi/gow/suomi1.html

Just thinking out loud here, but if you’re going to fit a monopod wouldn’t it be a better idea to fit it a folding one to the barrel shroud? It seems to me that it would be much easier to fold/unfold, it would give a bit extra weight to control the barrel with (Weight that could be shaved of the immensely heavy barrel) and give the weapon a lower profile which can’t be a bad thing.

Yeah, it would be a much better way to do it – like the ZK-383.

Leszek –

My compiments on another great article.

The pneumatic rate of fire reducer in the wz.39 would not have performed well over the long term if it was constructed of bare or blued steel. The chambers inside these devices alternate between pressure and vacuum phases during operation. During the vacuum phase, when the device returns to its original length, a moisture condensate (fog) develops inside the chamber as the relative humidity exceeds 100 %. The absolute humidity of the air in the buffer chamber (grams water/liter of air) does not change, but the remaining air inside the device can hold much less moisture in suspension as the pressure drops. This condensation quickly leads to rust which impedes buffer functioning.

This is why industrial pneumatic buffers are constructed of chromium plated steel, aluminum, stainless steel, brass, etc. Even using corrosion inhibiting oil, you cannot prevent severe rust in a steel pneumatic buffer. The same action which condenses moisture on the innards of the buffer chamber removes the oil.

With today’s widespread use of aluminum and stainless steel in firearms, a buffer could be developed to avoid corrosion damage. But did Pan Wilnieczyc have such materials available in 1939?

A quick question: Was the wz. 39 pneumatic buffer the pattern for the rate of fire reducer in Pan Wilnieczyc’s wz.63 machine pistol?

Not at all – wait till you see the PM-63 article I also gave to Ian. The rate reducer there is a purely mechanical thingy, with an inertia block disengaging a lever holding back the slide – very generally speaking somewhere along the lines of the Skorpion or Stechkin – but with the weight travelling horizontally, not vertically.

On the other hand, the so-called Zielonka Glauberyt prototype of the PM-63 successor of early 1970 revisited the pneumatical rate of fire boondocks – and with likewise results (ultimate failure). The Radom Glauberyt, still in the Police as the PM-98, has the mechanical ROF reducer, with vertical travel – but wait till you see this in yet another episode of Polish Sub Machine Guns on the Forgotten Weapons Dot Com. Until then, bye-bye, and stay tuned, folks.

I’m looking forward to the PM-63 article. ISTR that the only article I’ve read on the Glauberyt was also Leszek’s (in Small Arms Review, forget which issue or year).

As a matter of fact, these were those same articles – so if you know these already, you’ll find nothing new there in the text layer. Ian gives much more illustrations, though and does not separate articles between the the two ends of the issue 🙂

(BTW – if any of you is by accident also the subscriber for the Small Arms of the World electronic version of SAR, my 2006 PM-63 article is this week’s new addition to the library.)

Dear Leszek Erenfeicht!

I have questions.

What is your e-mail address?

My papa-din@mail.ru