Today I am in Vlašim in the Czech Republic, where Sellier & Bellot has allowed me to film a tour of their ammunition plant. This is one of the largest ammo manufacturers in the world, and they start with basic raw material like lead, copper, and brass and ship out complete case ammunition. The machines involved in this process are really interesting – let’s have a look!

Related Articles

Select-fire Rifles

Bigger is Better? The Bren 2 Battle Rifle (BR)

CZ has taken the Bren 2 design, and scaled it up to 7.62mm NATO as the Bren 2 BR (Battle Rifle). A decent number of military and security organizations are still interested in the larger […]

Semiauto Rifles

CZ Bren 2 MS: The Civilian Version of a Modern Combat Rifle

CZ’s Bren 2 is one of the more successful recently developed military service rifles, having been adopted by the Czech Republic and Hungary, as well as entering licensed production in Ukraine. The semiauto Bren 2 […]

Semiauto pistol

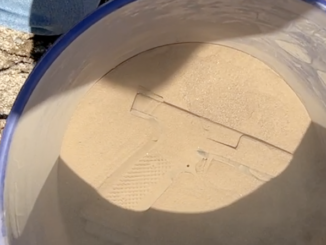

Laugo Alien: Sand Test (feat. Moon Dust)

Next up in our Maserati-or-Hilux assessment of the Laugo Alien, we have a sand test. First a plain, easy sandy soil immersion, and then a horrible bucket of moon dust. So…will it blend?

Awesome! Thanks man, I love “how it’s made” videos.

There is some crazy industrial design going on.

And once again, Ian proves his rock-star status by being allowed anywhere near the factory floor.

Very interesting. Thanks, Ian!

Love these type of videos. Thanks.

Great video. All of those machines are cool to see. Especially the number of QA stations and the optical tech used at many of them. Also great that you actually can see how most of those are doing their tasks.

Thanks Ian and thanks S&B!

Never realized how intensive the QA was. I have to wonder how intense the QA is for other manufacturers. There did seem to be a significant rejection rate.

The rejection rate of the finished brass was insane!

I don’t know how many parallel lines they have at that facility, but quite possibly if the whole thing were switched over to belted .303, it could keep one Vickers gun running 24/7.

“(…)belted .303(…)”

What is this?

OK, the .303 (with black powder) is actually two years older than the Russian 7.62 mm rifle cartridge. Dark Ages. But you cannot really plead ignorance, because the cordite loaded versions was adopted in the same year as your 3 line, 1891.

And we should not forget that Russia in 1908 switched to the same bullet diameter the British cartridge (and Paul Mauser’s 7.65 of 1889) had had from the start.

“(…).303 (with black powder) is actually two years older than the Russian 7.62 mm rifle cartridge. Dark Ages. But you cannot really plead ignorance, because the cordite loaded versions was adopted in the same year as your 3 line, 1891.(…)”

Wait. Are you claiming ·303 British is belted? I have always though it is rimmed.

Sorry, I thought your original comment was tongue in cheek.

“Belted” refers to delivering ammunition (rimmed or rimless) already loaded into machine gun belts by the factory.

This is one of the best videos you have ever done! Especially like the fact that many of the machine movements are driven by eccentric cams, a mechanical process that has been with us for over 200 years. But then QA/QC on every case, bullet, primer and cartridge is done by extremely sophisticated computer equipment from the 21st century. Really superb look at a process I take for granted when I pull the trigger!

Now we need a video to show the contrasting method.

3rd world guys sitting on the floor reloading spent steel cases.

I realize those are all over the internet, but seeing onevwith some good voice-overs explaining what and why would be cool.

Well, all the steel cases I’ve heard of were Berdan-primered because they were European designs. And I thought you couldn’t reload Berdan primers. So yes, I would be interested.

“(…)you couldn’t reload Berdan primers(…)”

It is less popular than with Boxer-primers but nonetheless possible, see photos at https://www.gunsamerica.com/digest/a-good-stuck-at-home-project/

Funny and interesting mix of supermodern machines and the old communist tools and machine. it is actually funny. btw Sellier and Bellot where french guys who escaped from France. I assume 1. half of 19. century? not sure now