One of the very first things I posted here on Forgotten Weapons was an article on a French rifle called the Hagen (it was designed by a Norwegian). I posted an article on it written in French by Jean Huon, but wasn’t able to read it. Now, thanks to reader Thibaud, we have an English translation of the whole piece. I did some editing to clarify parts where I could, but there are still some places that are a bit confusing. Still, this was quite a lot of work to translate and transcribe – thanks for taking the time to do so, Thibaud!

The Hagen Semi-Automatic Rifle

by Jean Huon

Studies of documents from several archives and documentation centers of the French Army show that many tests concerning semi-automatic rifles had been done in our country since the end of 19th century. There was both tests models developed in our own factories and foreign prototypes. Among these was the Hagen rifle.

This firearm was created by a Norwegian gunsmith, but many details make us think it was constructed in Great Britain: the similarity of the stock to Lee Enfield for one, markings “on” and “off” on the magazine cut-off lever, and pressure indicated in pounds per square inch.

The Hagen rifle test was anounced by the January 9, 1912 letter n°308S from General Michel, president of the Portable and Small Caliber Arms Superior Studies Committee, addressed to the Versailles Firearms Experiments Committee. The gunsmith representative should attend the tests and bring 2,000 cartridges with him. On February 22, 1912, the representative came to the committee accompagned by Captain Petit, secretary of the Portable and Small Caliber Arms Superior Studies Committee. He brought the rifle in question with 15 charging clips and only 20 cartridges. The representative disassembled the rifle, gave a brief description, and a few cartridges were shot as first testing. The weapon appeared interesting enough to proceed with further tests when the planned 2,000 cartridges arrived.

That ammunitions arrived for the Committee on April 23, 1912. Tests executed by the Committee focused at once on the rifle and on the powder used as propellant for the cartridges. Tests were recorded in a report written on July 26, 1912 and we recognize among signatures from the Committee that of M. Chauchat, who would go on to design the M1915 automatic rifle in three more years.

Description

The following description is intended to remain as close as possible to the original report, from which we borrowed large sections.

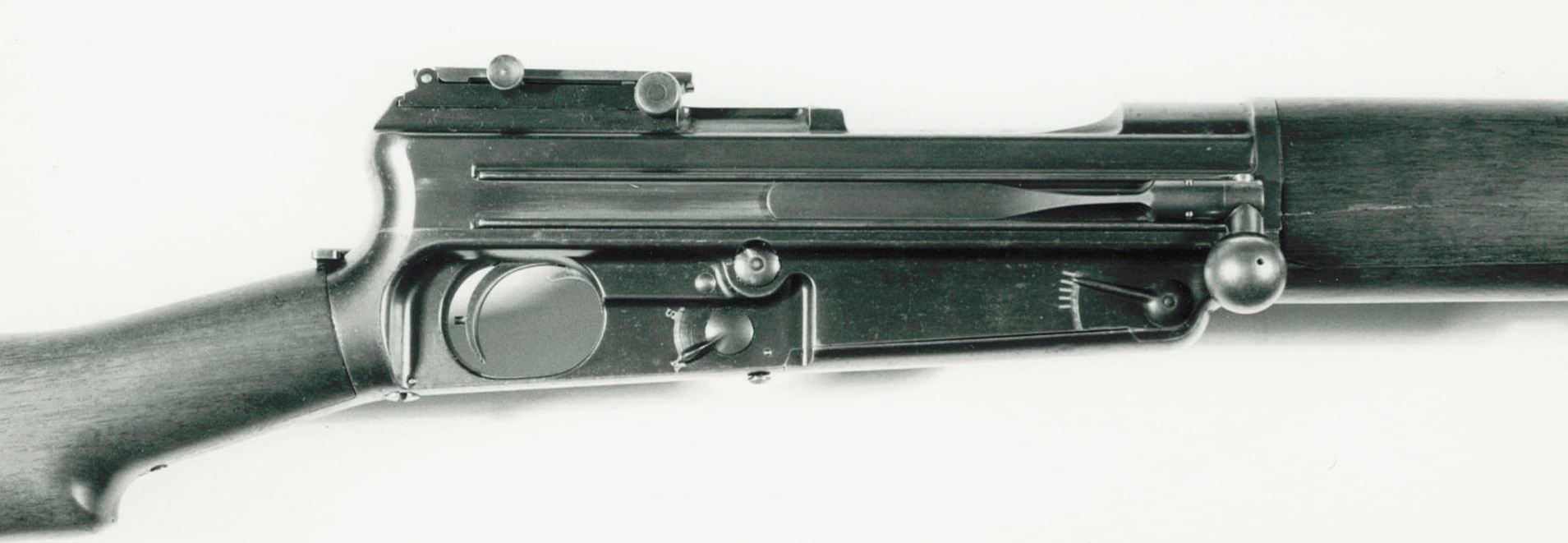

The frame, the receiver, the bolt, barrel, the gas piston, and the feed mechanism.

The frame consists of three parts: a permanently fixed barrel, the mechanism box with flying and butt plate; drum or handguard pierced by two cylindrical holes surrounding the barrel and the unit borrowing and gas which is mounted the sling; and a return spring.

On the underside is the assembly system which connects the slide-frame and the receiver.

The front side holds two small buffer springs.

The rear sight is adjustable for elevation and windage. It is composed of a fixed plate and a movable piece, which is graduated for distance shooting. On this ladder is an aperture which is locked at a selected distance by a spring loaded mechanism. When this graduated ladder is collapsed, shooter can use a specially designed ghost ring for very short distance shooting.

Elevation adjustment is controlled by moving the movable piece using a click-adjustable screw.

Windage adjustment is obtained by pivoting the fixed plate around an axle that is located on its front first quarter. It is operated by an endless screw linked to a cog-wheel machined in front of the fix plate of the rear sight.

The bolt is a cylinder with extractor, two locking lugs, two grooves for the fork’s lugs, one ejector groove and one groove for the firing pin’s nut.

The cylinder is pierced and inside is located the firing pin composed of a spike, a spring and a nutted hammer.

The barrel is screwed into the receiver and has a gas port of 1.15 mm diameter located 9 cm behind the muzzle. The barrel rifle is 4 lands and grooves rotating clockwise.

The gas piston system is composed of two parts, one of which is permanently attached to the barrel and the other is detachable. The part integral to the barrel constains the piston and its guide rod on which is mounted the return spring and the transmission fork. This fork is articulated on its front part and contains two plates, each of which has a lug linked to the slide and that allow the piston to transfer its movement to the slide.

The piston runs in a tube permanently attached to the barrel, and contains a flat spring that is intended to facilitate disassembly of the bolt [or slide, maybe].

The part that is not attached to the barrel is composed of a guide tube with a kind of mouth piece on its front end that is exactly adjusted to the canon. Assembly is done with an assembly key consisting of a semi-cylinder which is hold on the nosecap and a groove on the barrel. The nosecap holds an articulated piece, a bayonet lug and the front sight.

The upper part of the front sight is located in the center of a flat-conical piece defining the dangerous zone around the target.

The gas port is closed on the front face by a knob or “adjustment key”, which can be adjusted by a square part outside of the piece, this knob is pierced and had a diagonal groove. We can place the hole or the groove against the barrel. When the groove is against the barrel, the piston is linked to the gas port. When the hole is against the barrel, the piston is not linked to the gas port. In this case, the rifle is manually operated.

The firing and feeding mechanism is held in the receiver. The feeding mechanism, placed on the front part, is composed of a spring loaded elevator. It is locked by a plate and a lock and the elevator is composed of a plate with a hook on its rear part, a lever with a flat spring and a spiral spring activating the lever, leaning on the bottom plate.

The floorplate can be opened to unload the magazine. A display arm and graduations are placed on the right side of the receiver to show how many rounds are left in the magazine.

The firing mechanism, placed in the rear part of the receiver, is composed of a hammer worked by a spiral spring, a trigger with its coil spring, a sear with its two small coil springs, a bolt release lever, an ejector, a fire selector, and a security lever that can lock the trigger.

The trigger moves around an pin and, thanks to its elongated hole (around the pin), it can also move vertically. It contains a part that acts on the sear. The coil spring mounted on the pin and on the trigger can work both by pulling and twisting.

The front of the sear contains a kind of hook that acts on the hammer and its middle part has a “grip” to connect with the rear part of the trigger.

The bolt release lever allows the breech to be closed by a trigger pull or manually when the rifle’s semiauto mechanism is not in use.

The fire selector allows the rifle to be used in either semiauto or manual modes.

The mechanism frame (lower receiver) attaches to breech frame (upper receiver) using two lugs, front and rear. The rear lug is composed of two parts, of which the rear one, which serves as a wedge, can be removed with a screw. This allows the lower receiver to move forward and backward against the breech frame and, then, disengage the lugs from their housings.

The safety mechanism is composed of a semi-cylinder which can be placed with either the flat or the round side against the sear. When the round side is against the sear, it can not move backward and thus the hammer cannot leave the cocked position. A flag shaped indicator shows “off” (open) or “on” (closed) to alert the shooter to the state of the mechanism.

Function

The weapon functions either in semi-auto or manual repeating mode according to the shooter’s choice and indicator’s position.

When it is in manual configuration (“S”), the ejector acts as a bolt stop and the bolt stays to the rear after each shot. The ejector retracts when the bolt release lever ahead of the trigger is used.

When it is in semi-auto configuration (“M”), the ejector is turned downward, which lets the bolt move freely. The ejector moves upward only after the last round is shot and acts as a bolt hold-open.

When the rifle is loaded, cocked and its bolt is locked open, the shooter must release the breech with the bolt release lever. The shooter pulls the trigger, the sear operates, and the round is fired. When the bullet has passed the gas port, a part of the gas goes into the cylinder and pushes the piston backward. The fork moves the bolt, which is unlocked and moves backward. The spent cartridge case is ejected.

When moving backward, the bolt re-cocks the hammer, which attaches to the rear part of the sear while the piston compresses the return spring. End of the backward movement.

The return spring is then released, the bolt moves forward, and a new cartridge is fed into the breech. The bolt has two lugs, and rotates 30° to lock.

Testing of the Weapon

There was testing for functioning and ballistics. Ballistics testing intended to measure velocity, trajectory, and accuracy. This was done in comparison with rifle Mle 1886 M93 (Lebel), firing the Mle 1886 D (type ECP 192) cartridge.

Ballistic Testing

Velocity V25 was tested at 15° (celcius) with 20 cartridges.

Trajectory was measured under normal atmospheric conditions (t=14°C and P=750 mm) with 20 cartridges.

Accuracy was measured at 200 meters (220 yards approx), firing in single shot mode from a rest. Two shooters fired two series of ten shots each. Accuracy testing from rests was also done at 400, 600 and 800 meters.

We obtain the following results:

V25 is 777 m/s (2549 fps) from the Hagen rifle, which is 90 m/s more than the Mle 1886 D fired in the 1886 M93 Lebel rifle.

Trajectory is a little bit lower than with Mle 1886 M93.

Accuracy at 200 meters is quite equal between the two guns.

At 400, 600 and 800 meters, Hagen rifle is a bit less accurate than the 1886 M93 rifle.

Function Testing

This shootings was done from a rest. It consisted of 200 cartridges shot in strings of 50 with pauses from 25 to 45 minutes, allowing the rifle to cool down. After the 200 shots, the gun was stripped and cleaned entirely.

During these testings, the follow occurred:

- 18 closing on an empty magazine (bolt hold-open failure)

- 22 feeding failures (bad positioning of the cartridge)

- 1 failure to eject

The weapon was severely fouled, especialy in the breech and the locking lugs. It has been noted that bolt and fork were severely worn on their contact surfaces.

After complete cleaning, 200 cartridges were planned to be shot. After the second shot, the gas piston broke near the fork. Testing was then stopped.

At that point it was still possible to use the rifle as a manually operated weapon, but the operation was quite difficult because of the requirement to pull both on the bolt and operating the bolt release lever.

Conclusions

In its report, the comittee expressed various opinions on the Hagen rifle.

Pro :

- Low recoil

- Good trigger pull

- Simple firing mechanism

- Good accuracy

Cons:

- Heavy weight

- Poor balance

- Too short cocking handle

- Complicated sights

- Unusual feeding mechanism

- Insufficient durability of various parts

Characteristics:

- Caliber: 7 mm

- Total weight : 4.650 kg (10.25 lb)

- Total length : 1198 mm (41.2 in)

- Barrel length : 650 mm (25.6 in)

- Distance from balance spot of empty weapon to en of stock : 570 mm (22.4 in)

- Distance from gas port to end of the barrel : 90 mm (3.5 in)

- Distance from gas port to beginning of the barrel’s rifling : 504 mm (19.8 in)

- Diameter of gas port : 1.15 mm (0.045 in)

- Length of line of sight with rear sight down : 746 mm (29.4 in)

- Length of line of sight with rear sight up : 808 mm (31.8 in)

The cartridge:

The cartridge has a rimless centerfire case made of brass. It has a boxer primer and measures 56.5 mm in length. The cylindro-ogival ball is maillechort jacketed lead, weights 9.72 grams (150 grains) and measures 29 mm. Powder is 2.81 grams (43.4 grains) of tubular grains. Complete cartridge is 23.35 grams (360 grains) and 78 mm long.

This allows us to identify it as a 7 mm Mauser.

***

Results of this testing show that the French Army was interested in all news in armament technologies. We nevertheless note a reluctance at giving troopers a semi-auto weapon. We also must say that at the same time our (French) manufacturers already produced excellent prototypes of repeating semi-automatic rifles and, if we really wanted to adopt this kind of equipment, there was no need to adopt a foreign design.

Scan of the original text:

Thank you for another fascinating article. Kudos to Thibaud on his excellent translation. Well done. It seems that the coming of the 20th century was a watershed of experimentation and innovation in the firearms field. Looking at the cocking handle, there is a strong similarity to the recently featured Smith Condit in that area, while the flush trigger guard assembly is reminiscent of the Hotchkiss and Bergmann designs. I wonder how much is the result of studying other designs/patents, or simply the result of similar thinking about a common problem, as in having a cocking knob that resembles and can function as a bolt-action if needed. As to the Enfield-like rear stock and the markings, it is conceivable that the designer contracted with an English gunsmith to produce his design as a true “custom build,” unlike the fitting of common mass-produced parts that passes for the majority of custom gunsmithing today. (Quite frankly, I have to laugh at all the “custom built” AR 15s around. Heck, I put one together last night. I guess I am a custom gunmaker :)). Anyway, rant aside, I have to admire even these failed efforts at innovation, as there seems to be much more creativity in this period than there is now in our age of CGI and CNC. We truly stand on the shoulders of giants.

I reckon the Committee nailed it on their first and last comments. That is a too heavy rifle – one presumes without magazine. I didn’t notice magazine capacity. I did notice a lot of little springs which could leap into the mud, brush, dirty blankets etc if a thorough field strip was needed. Finally, there is an old engineering adage: “If a thing looks right, it probably is. If it doesn’t, it’s not”. Though not attractive, this is actually a beauty compared to the MAS 36. This was old and ugly manual bolt action compared to the sleek Garand and Johnson on the other side of the Atlantic which were semi-autos.

In fact, why have a manual option in a semi-auto at all? (Unless you expect a machine failure?)

There was a lot of archaic thinking in the Ordnance Departments of the various militaries at the time, and their requirements drove a lot of the apparent anachronisms in many of the “modern” designs, such as magazine cut-offs, 2000 meter volley sights, and the ability of the semi-automatic rifles to function as single-shots, not only with regards to reliability, but also regarding the idea of soldiers “wasting ammunition” with their new-fangled autoloaders, and the inability of conscripts to comprehend the nuances of maintaining a self-loading rifle in the field, or even in the barracks. Remember, many of the “old mossbacks” as the senior officers were often referred to, came of age in the time of muzzle loaders and single-shot breechloaders, and saw no need for anything more advanced than what they were accustomed to. Remember, there was a time when it was believed that airplanes, automobiles, and tanks could never replace mounted cavalry as a reconnaissance and breakthrough force. That doesn’t even begin to account for the economic implications of mass producing and fielding a million new self-loaders into service. As I said in another thread, I doubt that any autoloader would have been deemed “good enough” at the time to justify its acceptance as a standard service arm, although several, such as the Mondragon, did see limited use in WW 1.

The dual automatic/manual operation modes are similar to the Mexican Mondragon M-1893 6.5mm rifle. It was a manual bolt repeater, but had an “automatic mode” selector, that released the sear and fired the piece when the bolt was closed. As Hans Tanner describe it in an article in Guns of the World (Petersen, 1972);

Considering the close working relationship between the French and Mexican armies up to WW 1 (pre-Zimmermann Telegram, that is), I’m wondering if this rifle wasn’t intended for similar tactics; manual operation for precise shooting at long range, with (semi-)automatic fire to be reserved for close-in assault, etc.

On the plus side, simply using the bolt release lever to let the bolt return to battery would be less involved than operating it manually, as a “straight pull”- type. The bolt-release lever could apparently be operated by the trigger-finger of a right-handed shooter. Not a weapon for “southpaws”.

cheers

eon

Eon,

As usual, you provide excellent information.

The concept is definitely in-line with the prevailing thought among the upper echelons of most (if not all) armies of the day. Single shots at long range until SHTF, then get the lead flying. The concept still applies to a degree in modern armies equipped with select fire weapons, using aimed semi-automatic fire unless in danger of being overrun (at least in disciplined units). When your life is on the line, however, it is good to have a rapid fire option, whether semi-auto vs. manual repeater or full auto vs. semi-auto. Unfortunately, the guys that made the procurement decisions didn’t have their necks in the noose, so to speak, so the grunts were stuck with what they were issued.

I bet the magazine holds five rounds and is internal. See that nifty little lever with five little tick marks by it near the mag well front with five little tick marks? I bet that lever got snagged on absolutely everything…

I find it amusing that a 4.7 kg rifle was called too heavy in an era where 4.2 (Lebel) was considered fine. Granted, that’s pretty porky next to a Berthier carbine, but those are TINY rifles with a three round magazine.

I am not that surprized. It is 1.2m long with barrel little more the half. In addition, the return mechanism (gas port) starts about 0.1m from muzzle. Tat adds lots of mass/ weight. Heck, my vz.52 is lot shorter and it weighs in close to 4kg(well, it carries bayonet too).

Oh, I wish I could edit myself…

ian is there anything else that needs translating from whatever language to english ?

I’d like to mention one detail.

This is about gas port location. All guns of that period had gas port way forward, some way-way forward. That gives relatively very little time for gas pressure to act on piston/ return mechanism.

Today we have typically instead of 20-26″ barrels just 16″ long barrels and gas port is located somewhere at 60-70% of overall length from chamber. I am aware this has to do with pressure-travel curve, however such big change must be due to some other factors. Let me guess – different propellants?

Reminds me externally of a Mas 44 rifle.

It seems to me that it was also just the understanding of the time that that was the way to do it. Even Garand went that route, though his idea may have evolved from his ill fated gas trap.

We all have the ease of knowing about other materials to make lighter firearms, but I always feel sorry for the soldier of old.

Here you have this guy with a select fire rifle supposedly capable of taking out the enemy at 400 meters, BUT he has to lump a huge bayonet with it!

I’m always fascinated by the fact that if in 1914 the war would have been not so close (I mean before july-august of course) maybe one year later some french soldiers would have been equiped with the first modern mass-produced semi-auto infantry rifle firing a new 7mm bullet (meunier rifle ?)…wearing the famous red pants and the old uniform. Modernity meeting tradition.