Many people already know everything I’m going to say in today’s video, but I think it’s important to get it out there for the folks who don’t have as much mechanical experience with their rifles. Specifically, today we’re looking at how the AR uses direct gas impingement to operate, and how it’s different from the other DGI gun designs out there:

Related Articles

Shotgun

Ye Olde Tactical: A Vintage Riot Shotgun w/ Nydar 47 Optic

All that is tactical is not necessarily new…and this shotgun is a perfect example. It was put together by a Tucson police officer in the late 1940s or early 1950s, and has all the elements […]

Accessories

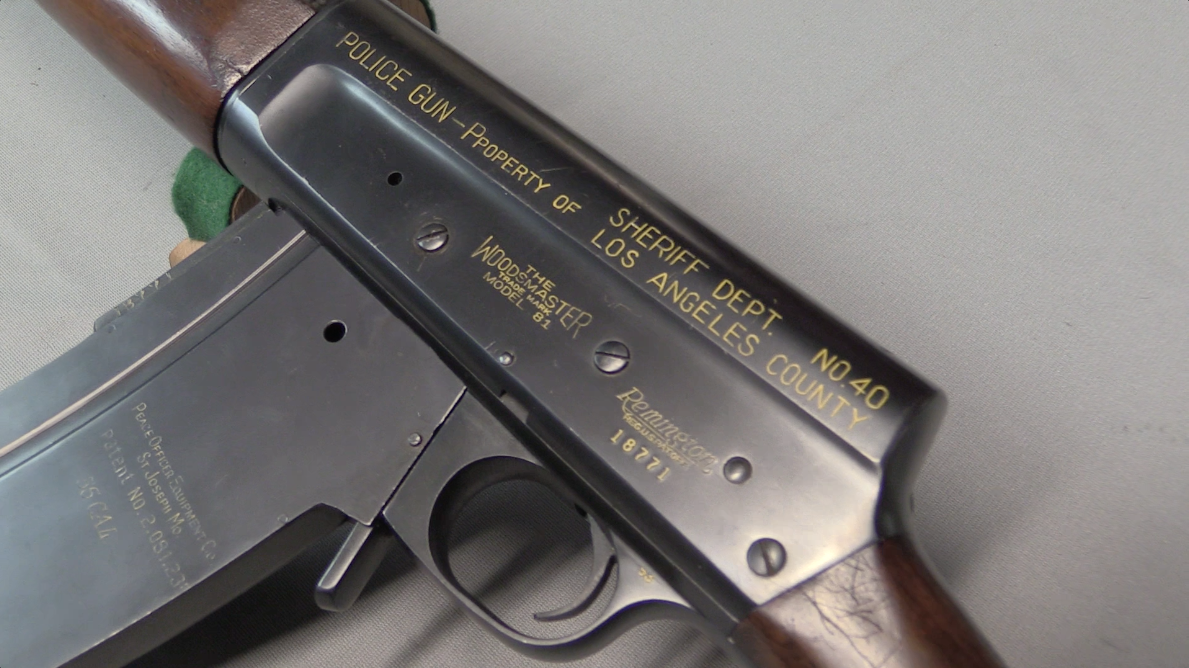

Remington Model 81 Special Police

The Remington Model 8 was one of the first successful self-loading rifles introduced to the commercial market, and it was designed by none other than John Browning. It was an expensive rifle, but popular for […]

Prototype

Norton DP-75: Titanium Plus German Police Pistol

This pistol is something of a mystery – its design comes from the experimental Mauser HsP of the mid 1970s. It uses a short recoil system with a pivoting locking block vaguely like a P38, […]

As Mr. Stoner stated in his patent, SN; 2951424, gas operation used in AR-15

was not a direct gas impingement system. It was a known gas expansion application

with a gas cylinder and piston located behind the breechbolt instead of usual

underneath or over the barrel. Main purpose doing this, was joining all recoiling

reciprocal movement elements on line with the barrel axis and therefore obtaining

minimal barrel rise. Today’s trend of adding another gas piston over the barrel

ruins the rifle’s design phylosophy and balance of parts mass.

are you referring to this patent (http://www.google.com/patents/US2951424?hl=nl) ?

Yes Juver, it was the patent gave birth of AR-15. If noticed, the stock shape

was not “ın line with bore axis” type which was known and applied at that time

to reduce barrel jump. Most probably, Mr. Stoner wanted to point out that,”even

in traditional stock shape, claimed on line configuration would provide minimum

barrel rise than common types”.

Regarding to mass ratio of locked and unlocker parts, it should be stated that,

this valuation is important for piston strike kind of gas operation and not for

“On Line Piston” of Stoner. As Keith clearly stated, gas pressure within the bolt

carrier also pushes the bolt forward as creating minimal resistance for lock

surfaces and required optimum momentum to start the bolt rotation is not critical

as being on piston strike kinds. However, there was no claim in the patent relating

this facility.

There is another small twist to the AR set up.

The gas acts equally all around the cylinder formed by the bolt carrier and on the piston formed on the bolt.

however, the weight (and hence the inertia) of the carrier is much greater than that of the bolt.

The effect is to shove the bolt slightly forward.

That lifts the locking lugs slightly off their seats – or atleast acts to counter any remaining chamber pressure acting to hold the lugs and their seats together.

so in theory, at least, a gas impingement AR opens its bolt with less heavy scraping as it rotates, compared to say an piston equivalent…

I’ve never heard of equivalent piston operated guns like the Piston AR15s, AR18 or that piece of British crap, having longevity issues due to bolt lug or locking seat wear – so, any advantage gained is not critical, and must be weighed against the problems of fouling in a system which allows gas to expand and hence cool more, and exposes more cold metal surface to further cool the gas and collect the fouling.

What would be interesting is if someone had a suitable scale and could measure the individual weights of the AR bolt and the bolt carrier assemblies. A document called “US Army Weapons Command Research and Engineering Directorate Small Arms Systems Laboratory Technical Notes on Small Arms Design, May 1968” which Ian previously published here (at least I think this is where I got it from) explains some design guidelines for rifles, including bolts and bolt carriers.

This document states (on page 71) that the “mass ratio” of the weight of the “primary mass” (piston, operating rod, bolt carrier) and the weight of the “secondary mass” (bolt assembly) should be “at least 3”. That is, the primary mass should weigh at least three times as much as the secondary mass. It describes the AK-47 as having “a mass ratio of 5.4, a highly impressive figure”. It doesn’t however give any further examples. I gather the fundamental issue is that much of the operating cycle of a typical gas operated rifle depends on the inertia of the moving bolt carrier rather than the residual pressure of the gas.

An AR type action looks as if the ratio would be much lower than many other rifles because it has no piston rod, a small bolt carrier, and a large bolt (because of the gas rings). The MAS and the Ljungman/Hakim also don’t have piston rods, but they do seem to have fairly large bolt carriers. It would be interesting to know how the mass values for a typical AR type rifle fall within the design guidelines mentioned above.

However, don’t forget to factor in the mass of the buffer. It has to move as well.

And the mass of the hammer and spring as it has to be reset.

As much as DGI was in AR form a novelty one time, I believe it went stray path and obviously is remaining on it. There was since its implementation and introduction to military of United States no new design of this kind introduced. There is surely reason for that. And no wonder; who had ever chance to see drawings of Bolt and Bolt carrier is struck by precision of three sets of diameters and cost involved. In addition, the system is inherently dirty. There is also no efective way to clean long gas supply pipe. I would not call it ‘user friendly’ system.

By the way, the mentioned offset between pipe or piston and its effect on weapon climb is IMHO overplayed. What has effect on climb is primarily shape of stock and shooter’s stance. If it ever was a concern it was solved or attempt to that effect was made in one German and one Czech rifle, in form of annular cylinder.

I like to add that I appreciate this seemingly ‘know-all’ fact and bringing it to attention. It never hurts to look at familiar stuff again.

The annular cylinder design is awful for other reasons, though.

Reading all the input from the obviously highly-knowledgeable and very experienced Forgotten Weapons crew, I nevertheless feel obligated to put in my two cents’ worth based on long-term practical personal acquaintance with the M-4 and M-16 in their original direct-gas impingement form. Slightly-enhanced simplicity? — Yes, since there is no gas piston mechanism present. Better resulting performance? — Definitely not, and this negative feature far outweighs the elimination of the conventional gas piston. I was obliged to spend many years in the armed forces working with DGI M-4’s and M-16’s in assorted forms of one sort or the other, and I did not find that any of them provided equivalent, let alone superior, functionality compared to conventional gas-piston systems, regardless of enhanced maintenance intervals and assorted other “tricks of the trade ” employed to better the reliability quotient of the M-4 and M-16. In fact, the very opposite was quite true. It stands to reason that DGI will result in accelerated carbon fouling and therefore require more maintenance intervals, no matter what the pundits say. Facts are facts, and no measure of emotion, rationalization or opinionation is going to change that.

Having said this, there is certainly little that is wanting in the current DGI system used in the M-4 / M-16 / AR-15 / AR-10 series of weapons, as long as regular proper maintenance is carried out in the field. This has been borne out by the overall reliability of the system in decades of combat in a wide variety of harsh environments, provided PROPER REGULAR MAINTENANCE is part of the equation. And therein lies the difference between a DGI system and one that is piston-operated : all else being equal, the latter is far more tolerant of misuse and abuse than the former, but I want to stress that one should always strive to conduct scheduled maintenance intervals on any gun — it’s simply a good housekeeping habit that will keep you, and your firearm, in mechanical readiness at all times. I used the L1A1 and assorted AK-47 / AKM variants in that same time period, and to this day much prefer the gas piston operation of these and similarly-equipped guns, which is why I still own an FAL and vz.58 rifles as my first-line guns. Bear in mind this is my personal preference based on experience, and that I really enjoy the M-4 / M-16 / AR-15 / AR-10 tremendously and have them in my inventory, but they are still not my first preference in a worst-case situation.

Hi Earl

this is an honest, unpretentious account you are laying out here and thanks for that. This talk should not be about bashing DGI of ARs, but on the other hand why to glorify something, which does not deserve it. I am not saying the AR is inferior by any means, but they are not superior either. My first experience with it just popped out as I picked it up: this thing is wiggly! Really – when you hold one part and wiggle the other, there is significant movement about connecting pins. Now, IF buttstock and barrel were part of same unit, all would be fine. In reality thought it is not so. What effect it has on practical accuracy we get guess.

By the way, after so many times before, I went yesterday to review some materials on SIG550. Man, this is a RIFLE. I know, fancy and tad too heavy – but it has all the bells and whistles. Sure, westernized AK, but done right way. Can something come about even better suited to current circumstances? Yes, of course!

You’re welcome, Denny. Yes, the SIG550 and its derivatives are very well-made rifles. The SIG556 variant has become quite popular among police departments and SWAT units here in the U.S. when they are able to afford it.

Was the AR you handled a used weapon? AR’s tend to wear down their connecting or takedown pins over time with heavy use and replacement kits are offered by several aftermarket manufacturers. With sound pins in place, the better-quality versions of the AR ( Armalite, Bushmaster, RRA, Smith & Wesson M & P, etc. ) are as rigid in the receiver area as any other military-grade rifle. One sometimes hears criticism of looser tolerances in the lower and mid-level AR’s from other manufacturers such as Olympic Arms and DPMS, but those criticisms sometimes also come from very particular AR aficionados. Either way, most name brands of AR are generally reliable and nicely balanced, and fulfill their intended role satisfactorily.

One outstanding feature of the AR that endears it to many, especially gun builders, is its modular construction which makes customization easy. In addition, there is an enormous aftermarket in all kinds of parts and accessories which support this at a more-or-less reasonable price point, which also explains its extreme popularity in this country.

What you said also reminds me of the AR-18, which was originally meant by its designers ( including James Sullivan of Armalite fame ) to be a second-generation, short-stroke gas piston-operated replacement for the M-16 / M-4 / AR-15, and which was intended to address the shortcomings of the former. The AR-18 was everything the M-16 and its derivatives were meant to be, and then some. It was simpler in design and construction, had a welded stamped steel receiver instead of a forged and machined aluminum one, was generally less complex yet better-built, and was easier and less expensive to manufacture with fewer resources and skills. It proved to be very accurate and reliable during U.S. Army trials but, like so many fine weapons with great potential, it fell by the wayside due to bad market timing. In the case of the AR-18, the U.S. Army was already committed to long-term mass-production of the M-16, and they had no interest in yet another alternative 5.56mm infantry rifle. This proved to be the AR-18’s undoing as far as sales and general acceptance were concerned. Limited numbers were made under licence by Howa of Japan and Sterling Armaments of the U.K., but it never saw widespread adoption. In spite of this, the AR-18’s operating mechanism inspired a whole generation of weapons such as the Enfield SA80, STK SAR-80 and SAR-88, Steyr AUG ( and all its derivatives ) and H & K G36.

The AR-18, as originally made, did have some weaknesses, eg., the folding buttstock was not as rigid as it should have been due to loose tolerances in the hinge mechanism, and the early pre-production guns proved sensitive to the type of ammunition used. However, these were all relatively minor issues that are normally associated with any prototype gun design, and could have easily been rectified on the production line as the design matured.

It is a pity that the AR-18 was never given a chance to realize its considerable potential — the small-arms world of today would be very different if history had allowed otherwise.

Jean Huon, in his book “Proud Promise” (Collector Grade Pubs.) mentions that the DGI system was first developed in 1916 by a certain M. Rossignol ca. 1916 during the attempt to develop a light machine rifle for the French Army…the DGI system was adopted by the French in their MAS 44 and subsequent iterations of that rifle – back in the early 90s a bud bought a MAS 44 and I busted his stones for buying a rifle for which ammunition was not available in quantity at the time – still ain’t!!!

CB in FL