“Carbine Williams”, aka David Marshall Williams, has a reputation as the designer of the M1 Carbine, and a very colorful history. He was a moonshiner who pled guilty to second degree murder of a sheriff’s deputy and served time in prison. He gained a reputation as a gunsmith in prison, fixing the department’s guns in the prison shop, and was eventually allowed to work on his own firearms designs. Eventually released, he patented a design for a gas tappet system. The system was used for the M1 Carbine (that was really the extent of his contribution to that design) and a related “floating chamber” system was used in a .22 rimfire conversion of the 1911 pistol and the M1919 Browning machine gun.

The Colt Service Model Ace used William’s floating chamber concept to improve their previous Colt Ace .22 1911 conversion. The first prototypes were ready in 1932, and production ran from 1935 until 1945 (plus a reintroduction from 1978-1982). Most sales went to the US military, which bought 13,808 complete pistols and a bit more than 2,000 conversion kits. They were used for marksmanship training, as .22 rimfire ranges could be built in many more places than ones safe for full-power .45 ACP.

The Remington model 550 22 rifle uses this floating chamber to shoot 22 short, long, and long rifle interchangeably.

“(…)floating chamber concept(…)”

This also was patented as US2090657A https://patents.google.com/patent/US2090657

Ian, thank you so much for illustrating this. Have heard of the “floating chamber” .22 1911s for at least a quarter century if not longer without knowing what the mechanism was. So simple yet so effective – and oddly not that different from some of the .22 WRM & 5.7x28mm pistols on the market today that use blowback w/ floating barrels today.

Good luck w/ the new YouTube censorship policy, and I expect we’ll be watching you on a different platform soon.

Functionally they’re almost opposites. The floating barrel delays opening to facilitate blowback operation with a hot cartridge and reasonably light recoiling mass (I’ve gotten outstanding results using an updated version of this principle). The floating chamber increases blowback momentum / recoil to enable reliable functioning and realism with underpowered rimfire ammunition and a heavier slide.

What new policy ?

Question. Does the floating chamber move because gas is pushing it back by filling the space between the front of the chamber and the rear of the barrel, or, does the expanded case pull the chamber back with it during ejection. Thanks

The former. The expanding gas fills the space and begins pushing back on the chamber unit before the extraction stroke begins.

It’s a classic example of effective use of mechanical “dwell time”.

clear ether

eon

Popping out primer sort of early Garand thing? “Not saying it is, I am asking you.”

The floating chamber moves both because of the high pressure gasses filling the space between the chamber and the barrel (but you can see in the original patent that the case is slightly longer than the chamber, so the space is created, and filled by gasses, only when the chamber already started moving rearward), and because, due to the expansion of the gas, the case of the cartridge is stuck to it, and the case of the cartridge is pushed back by recoil (that’s also the pressure of the gasses into the case).

In respect to a standard blowback system, the floating chamber eliminates the loss of energy due to the friction between the case and the chamber, when the case is pushed back.

It can be said that functionally, it’s the opposite than the chamber-ring delayed blowback, that instead works by enhancing the friction between the case and the chamber.

Williams probably came up with the floating chamber independently

however, an earlier patenting of the idea was be Clausius, in 1900, three months before Williams was born

https://www.forgottenweapons.com/clausius-model-1895/

it also appears that Clausius came up with a floating barrel system, later used by the ill fated Kimball blow back pistols in .30 carbine

Does the Kimball barrel float? I thought it was a fixed chamber-ring system like the Mann or Seecamp. It sure looks fixed in Ian’s video. He never disassembles the barrel, but he does show a closeup of the chamber while resting the pistol on the muzzle, and it never moves.

“Does the Kimball barrel float?(…)”

According to advert shown at https://tincanbandit.blogspot.com/2021/10/featured-gun-j-kimball-arms-co-pistols.html

…patented floating barrel action of the KIMBALL AUTOMATIC reduces

recoil to a minimum, keeping muzzle jump to about three inches. This

makes possible more rapid firing and with greater accuracy [unreadable] heretofore

possible with a pistol of this power…

Mentioned patent is most probably US2846926A is available https://patents.google.com/patent/US2846926A

Daweo,

Wow, thank you very much! I didn’t realize that was part of Kimball’s idea, and thought I had come up with something new. Oh, well, I wasn’t planning to sell it anyway.

the kimball floating barrel idea is also used on the .38 special colt “gold cup” 1911

in combination with an internally threaded chamber.

sorry, forgot to add that the .38 special 1911, is blow back

Keith,

Excellent, thanks! That’s how I did it – much easier to run a tap than turn internal rings.

My recollection of using a Service Model Ace (made in the 1980’s IIFC) compared with a .45 ACP 1911 was that its felt recoil was clearly less than the .45 but due at least in part to the greater mass reciprocating a lot more than standard .22 pistols of roughly the same weight. This, combined with the same ergonomics and manual of arms and cheaper ammo, made it an excellent way to transition shooters from .22 to .45 1911 pistols.

Thanks for reviewing the Service Model Ace, Ian. I inherited one of the newer ones built in 1978 and on it the ejector is not pinned to the barrel as in the example you showed.

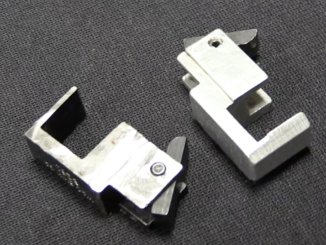

I built a conversion kit utilizing the floating chamber to allow conversion of a standard 1911 by merely changing the barrel and magazine. Enough energy can be harnessed to move the standard slide and spring. It dealt with the challenge of center fire vs rim fire with an off center chamber. I liked the idea of a conversion kit that could be carried in a magazine pouch. I had hoped to draw interest from a manufacturer with the horsepower to produce it but no such luck. But, I proved it can be done. It even locked open on the last shot.