Since we just took a look at the final American iteration of the magazine-fed Johnson LMG (the system would live on briefly in Israeli service as the Dror), we should also take this time to consider the belt-fed variants of the Johnson as well.

While the final round of testing was still being done on the M1944E1/M1945 Johnson LMG, the Ordnance Department had made up its mind to combine the tactical roles of the BAR and M1919A6 machine guns into a single weapon, to be called a squad automatic weapon (the Johnson may not have become the first one, but the name remains with us to this day). The weapon that Ordnance requested for this role was required to have a quick-change barrel, belt-feed system, folding bipod, straight-line stock, and select-fire capability with full-auto from and open bolt and semiauto from a closed bolt.

While several prototype belt-fed BAR designs were proposed to meet the requirements, the Johnson LMG was very close to fulfilling the role as it was, needing only a change to belt-feed. In an effort to win a contact for this new weapon, Johnson Automatics quickly drew up a design for a belt-feed mechanism to replace the magazine feed of the M1945 LMG. The fact that the gun already had a modular, removable magazine well was likely a big help in getting the design completed on April 27th, 1945. It was promising enough that Johnson won an $80,000 contract on May 23rd to finalize the design and supply two sample guns for testing. The two guns were completed and delivered in August of 1946, and given the official name T40.

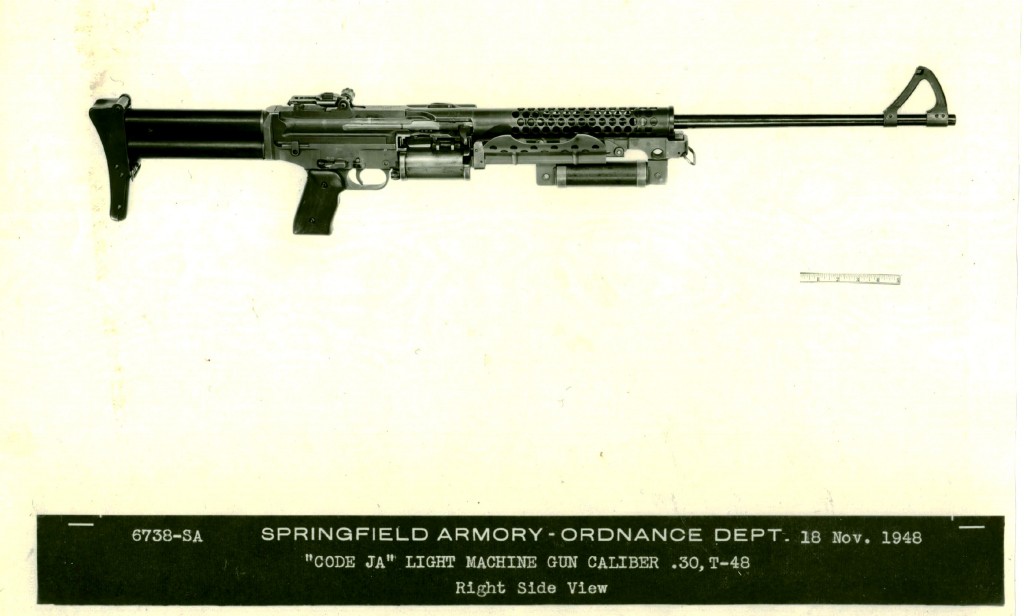

Two further projects followed the T40 – the T48 and T53. Both were chambered for the new T65 cartridge (which would eventually become the 7.62x51mm NATO), and both were designed to have interchangeable feed systems, so they could use either 20-round box magazines or disintegrating belts (although this did require swapping out feed components, rather than having both functions simultaneously like the more recent M249 squad automatic weapon). The T48 prototype was delivered by Johnson in February 1947 and the T53 (which was rebuilt from one of the initial T40 guns) in December 1947. The evolving design was required in large part because despite the apparent modularity of the Johnson design, the belt feed system put much more stress on the gun’s receiver than it could easily handle. The other parts of the gun apparently stayed generally faithful to the M1945 design, including the gas-assisted recoil action.

This was a continuing developmental process, but as it was progressing the Johnson Automatics company was losing its financial footing (and the urgency of small arms development had been largely lost when the war ended). By early 1948, the whole project was abandoned. The M60, from a separate developmental lineage, would end up filling the role that the Ordnance Department envisioned for the new automatic weapon.

References:

Canfield, Bruce. Johnson Rifles and Machine Guns. Mowbray, 2002.

“Belt-fed BAR”? Sounds… unique.

The British Army also experimented in this area, with a belt-fed Bren prototype, the X11E2, and a similar gun from B.S.A. They eventually adopted the FN MAG 58 (basically the same as our later M240) as the L7 series.

Back in the Bren’s original home, the Czech Republic, the Model 59 GPMG was basically a ZB26/Bren family gun converted to belt feed. Its predecessor, the Model 52, was even closer to the Bren, being able to take either a belt or a top-mounted box by changing the feed unit.

The most obvious advantage of belt feed from either side on the BAR would be that you would no longer need the “offset” operating rod to route the piston impulse to the bolt around the magazine underneath. A “straight-through” system like the MAG/M240 would be practical.

On the Bren, you could have ejection to either side rather than straight down, again eliminating the need for an offset operating rod.

cheers

eon

In Soviet Union the belt-fed RP-46 “Company machine gun”

http://en.wikipedia.org/wiki/Degtyaryov_machine_gun#Variants

was developed from DPM machine gun. It can also used the magazines of DP. It was adopted in 1946 (as you can except after RP-46 designation) but it was effect of earlier works – Л. Л. Дубинин and И. П. Поляков constructed the belt-fed adapter in 1942, but it was considered unsuitable for field use due to big mass (10-11kg).

edit: this is of course mass of machine gun and adapter not adapter alone.

I’ve handled an RP-46, but not fired one. It was a pretty clever idea…

Dumb question: Considering that the RP-46 was “flexible” to accommodate pan magazines or belt feed, wasn’t it somewhat heavier than what would be needed? With no way to fire a belt-fed RP-46 on the move (no way to hold the belt box), the arrangement would seem unnecessarily fiddly, as the belt-feed module is actually separately made, as mentioned above. Generally, I find that firearms that try to be “flexible” in ammunition feed tend to be heavier and more complex than is needed…

Andrew;

Generally true. This was one reason the Stoner 63 system relied on one basic chassis with various barrels, feedways, etc., for different roles. The idea being to only cart along the specific bits you needed while the rest stayed home.

Even more up-to-date examples have problems. The dual feed system of the M249 being a case in point. The springloaded flap tends to not stay put when you’re trying to use the belt feed, allowing “environmental factors” entry into the feed system, and the gun itself doesn’t always feed reliably from the M16 30-round magazines. According to friends who have used it on ops, the usual solution is securing the flap over the STANAG magazine well with 100mph tape, and using the 249 as a belt-fed gun, period.

cheers

eon

But still remember that Soviet Union produces Maxim 1910 machine guns to the end of WW2, at this was their main Medium Machine Gun despite the SG-43 officially enter service on 15 may 1943. So the belt-fed RP-46 was big leap in development of portable weapons with big firepower.

Hi eon

I disagree (exceptionally, nut I have to) with your assertion that there is relationship between Vz24/30 which was base for Bren and Vz.52 and later Vz.59. The differences are along several lines – mainly operating and locking systems. While Vz.26 was locked by tipping bolt, the latter gun has rotating lock piece similar to Vz.58 rifle.

http://forum.valka.cz/viewtopic.php/title/CZK-vz-59-UK-vz-59/t/12479

The Vz.59 is not as good weapon as Vz.26 (part of firepower) but perhaps better than some other universal MGs. Hard to tell if as good as PKM but likely not better. It existed in export version for 7.62 NATO. Czech military is currently re-arming for Minimi in 7.62 calibre.

From Small Arms of the World, 12th Edition, p. 394;

Looking at the photo of a field-stripped Model 59 on the previous page (p.393) and a field-stripped Bren (p.330) or Model 52 (p.398), there seems to be very little functional difference between the three. Except, as you state, the Vz58-type locking piece of the Model 59.

I wonder if, like the VZ58, the Model 59 can be assembled and fired without that locking piece? Not that I’d try it; nasty things happen when you absentmindedly leave the locking piece out of the ’58 and squeeze the trigger on a loaded chamber. In fact, it’s a lot like that Ross rifle in the new opener on the video. (Boom! in the wrong direction.)

cheers

eon

Yes sir – pretty close. While we should be discussing Mel Johnson’s gun(s) I do not mind to divert a bit while I get some audience. :)))

I happened to be an armourer as part of my compulsory service in late 60s and was involved extensively with mentioned MGs and rifle in addition to SG43 (tank version), machine-pistol Skorpion and several RPGs. That said does not make me qualified in every aspect of it. My take on comparing Vz.59 with older and much widespread Vz.26 which saw action in Asia and in Europe on both sides, may not be necessarily correct. Reason being – Vz.59 did bot get the opportunity. But yes, part of malfunctions with blank ammunition it was not really a bad gun. I have my objections, but keep them to myself pending future article on that gun.

When comes to ‘risky behaviour’ like firing without lock, well…. I do not know what extent of damage would be. Chances are that operator would not end up exactly in same state as he started. To my knowledge nobody tried that. Of cause, in heat of battle it was entirely possible to miss insertion of this part during re-assembly. To prevent it, somehow helpful was the fact that pieces of action were heavily chromed and as such they stood out in dark.

Not really. There is a solid incremental development line from the BAR to the FN MAG58. You can see a nice sampling in Swedish flavor on this page with BARs at top and converted to almost 100% MAG at bottom http://gotavapen.se/gota/artiklar/kg/swedish_kg2.htm

Kinda depressing that the US could easily have gone from BAR direct to M240-equivalent in the late fifties and skipped a third of a century or thereabouts messing about with inferior machine guns….

FWIW: FN was playing with belt-fed BAR before WW2 started. I’m pretty certain that I’ve posted links here before to the US patents.

Here is one of the FN patents:

https://www.google.com/patents/US2136512

Here is an even earlier attempt from the US:

https://www.google.com/patents/US2032376

A search for the inventor, Wiley T. Moore, indicates that he was pretty prolific.

Mr. Watters, I hope not to confuse you with someone else (maybe Watterman?) known from previous firearms design activities, let me ask you question.

It is known that FNH did considerable effort to take development of M240 to the utmost – in form of M240L. What do you think of Barrett’s involvement in further bettering of this already “milked-to-max” design? In this video they say that they saved another 2lbs:

http://www.youtube.com/watch?v=bIUp1f9f6KU

I’m not a firearms engineer, but I do track the history of these developments. I’d be surprised if you are confusing me with Harold J. Waterman, Jr., formerly of Colt and Marlin.

It is my understanding that FN’s approach was to substitute Titanium and other lightweight metals in the legacy design. Chris Barret’s approach was to cast the receiver in two halves, allowing him to eliminate the rivets used to join the individual receiver plates and internal assemblies. The casting also allowed him to thin the receiver in non-essential areas, which would be too costly to accomplish in the legacy design by machining individual receiver plates.

Here’s a link to Barrett’s patent for the M240LW:

https://www.google.com/patents/US7937877

Fair answer, thank you!

My guess was coming out of your obvious knowledge of gun related topics.

As far as the technique used by Barrett it is bit of surprise to me that cast as opposed to forge would qualify for endurance. I will check out the patent.

I’ve always felt that the Johnson in 7.62mm NATO would have been the perfect cartridge for the design….and as a belt feed type….it was perfect. The .30/06 caliber was way too powerful for the weight/design of the weapon.

The performance figures achieved for the military loadings of .30-06 and 7.62x51mm are identical, the difference only arises with civillian loads for heavy (greater than around 180 gr) bullets.

Perhaps it’s just me , but it does seem to be a bulkier belt-fed version of the famed( and supposedly back in production in Germany ) FG 42

The only FG 42 belt fed that I know of is the Light Automatic Machine Gun T44. And that seems to have had a side feeding mechanism like the prototype belt fed Kalashnikov.Where as the Johnson belt fed seems to have a bottom closing mechanism like the HK 21.

patent Belt-Fed Johnson LMGs

https://www.google.com/patents/US2655837?dq=ininventor:%22Melvin+M.+Johnson%22&hl=pt-BR&sa=X&ei=ju70UuTQJ4P70gGzs4DIDA&ved=0CDQQ6AEwADgK

I wonder what kind of links this gun used. It could not have been the M1 link because it works on the ‘withdraw’ principle and from the looks of things, this gun uses some kind of ‘push-through’ link or continuous belt, similar to the later American M13 link or the contemporary German Gurt 34 machine gun belt.

It was a push-through, disintegrating link. Canfield describes it as being similar to the German MG81 belt.

The 11 kilograms and heavy machine gun??

How about MG34 and MG42 German soldiers used to carrying…

The MG34 and MG42 way heavier and way better than those listed above,I had Fired MG13,MG34,MG42,MG08 Mauser and MG15 Bergman,the ones I didn’t fired in range was MG81,MG131 and MG151…

I can compare about those models,MG34 and MG42 are satisfactoral machine guns to be used,both 3 MG34,MG42/3/53/74/39 and MG81 are sensitive if belt get twist a bit sideway so this will cost jamming…

Rather than those issues there is nothing to complain about those MG’s,everyone criticize Germans but their weapons proved major respect in construction,meintanance and field performances..

As from my MG’ rating I place MG42 on 1st place among any machine guns in world,both MG34,MG81 and HK21 would be placed on 2nd place,number 3 would be Russian PKM,number 4 FN Minimi or simply SAW49,number 5 FN Mag or M240,number 6 Czech Universalni Kulomet VZ59,number 7 Russian RPD Degtyarev,number 8 USA M60 series,number 9 Singapore Ultimax,and finaly number 10 Japanese type NTK62..

As to be reffered to tactical and technical characteristics,those models placed in exact order how they proved to be by performances,quick to be deployed and used,field meintanance and cleaning,numbers of moving parts,maximum weight with and without ammunition,quick adaptation to be mounted on vehicles,naval units/aircraft,ability to be mounted on tripods and deployed emplacemants,transportation and storage…

So by firing most of them minus Japanese type 62 NTK here is the conclusion which is super simple in construction,high rate of fire,acuracy,mounting variation,long range,less numbers of gunner squad or service mans….

When I was in gun range I had one guy who assist me and his name was jake,he help to guide ammo so it wont get jammed,this is very important when firing MG34,MG42 or MG81 belt always have to be slightly lubricated by gun oil or even gear oil,by doing this you will avoid parts wearage and longer serviceability of gun….

So one man can operate MG42 without any problems when other crewman or assistant keeps ammo belts straight,I still think the issues with jammed belts is related to use ammo belts unlubricated so they will get stuck slightly…

As ammunition for those who owns MG42 avoid original German WW2 brasscased ammo science it not purely brass made,its mixed with lead to simplify massive production of ammo and that case is very weak and soft..

By using such of ammo the shooted case would get raptured in chamber,by selecting Indian type 8mm ammo you would run out of battery and A neather you get injured or B gun get damaged,both Indian and Egyptian ammo read Field headspacing gauge specses and particular ammo must be avoided…

For better A grade results Use original German WW2 steelcased or copper washed steel ammo,Romanian steelcased ammo and Yugo ammo those are satisfactory and original Field headspacing gauge read which is SAAMI specefications..

After shooting most of those guns, I beg to differ with your opinion. High rate of fire is a bad thing! The higher the rate, the harder it is to control the gun and the fewer bullets from any burst that land near the target. Forget about hitting anything with anything but the first shot. Our sister unit in Germany on my first tour was a Panzer Jaeger Battalion. We would send some of our teams down to their base for training and testing and vice verse.

The one thing every one learned was that the lower rate of fire of the M-60 made it many times easier to control and get hits with than the MG-3, which was the 7.62X51 NATO Caliber version of the MG-42. Which itself was a lower rate of fire version of the original MG-42. By the way, does anyone here know the history of the rate of fire of that gun and what and why they changed it?

Hi Stewart

As far as I know, there was an option/modification made to MG3 during its conversion from previous MG42. Part of ammo type it was heavier bolt which brought ROF down to 800-850 RPM. At that point you can call MG3 nearly ‘perfect’ MG ever made.

In reference to precious Val’s comments I’d like to ad that I appreciate his first hand, albeit perhaps limited experience. On my part I’d also felt similarly with perhaps exception of 5.56 Minimi. I consider it one of the worst in the bunch; almost anything else is better. Reason for saying it is mainly its terrific dispersion which is product of barrel holding device design.

The last defenition are mistakened where said Field,it says go gauge specses,mistyped..

Looking back over the comments from both Johnson LMG posts, I surprised that no one mentioned the TRW “Low Maintenance Rifle” since the Forgotten Weapons post a couple of years ago appears to be the main source of information about this forgotten, but promising, prototype. And like the Johnson and the FG-42, a pretty neat side-magazine buzzer that would have been right at home in the Star Wars movies. I understand why the incredible availability of M16s after Nam kept the weapon from being manufactured in the 70s but it seems like there have been several times since then when a reliable, low-cost, low-maintenance open bolt squad gun could have found a niche. And in addition to using STANAG mags, it wouldn’t be all that difficult to modify it to use SAW belts. (Or would it, for reasons not apparent to me?)

What were cost per unit during WW2?